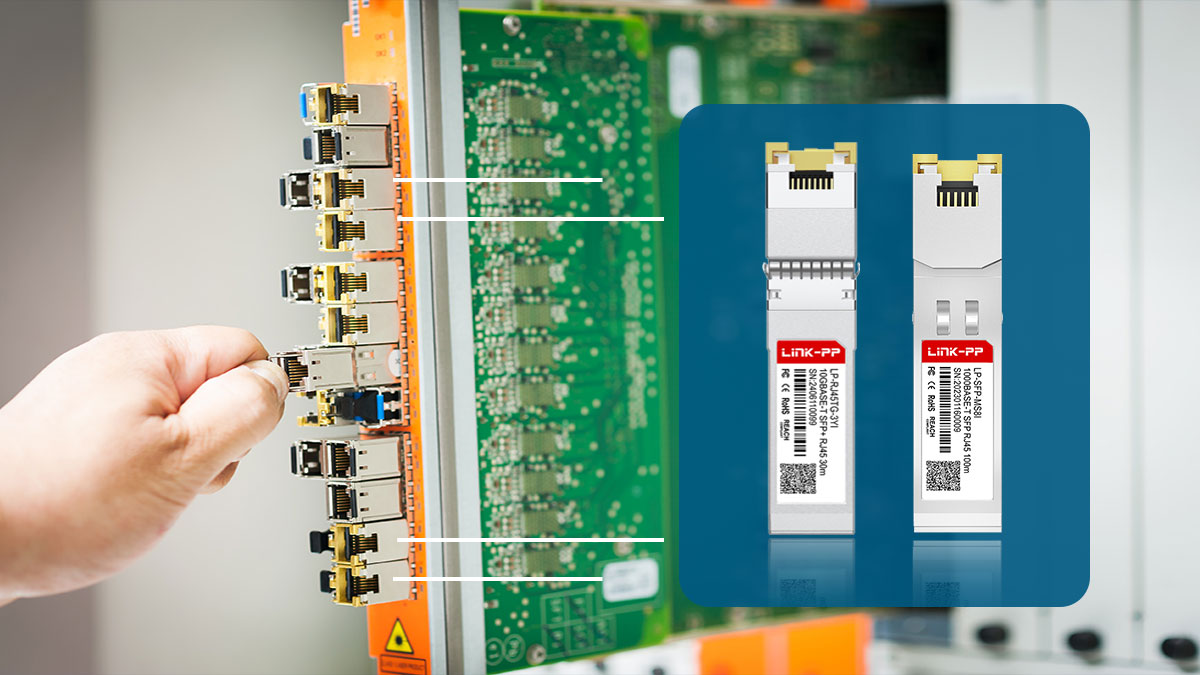

Copper SFPs (Small Form-factor Pluggable copper transceivers) are compact, hot-pluggable modules that convert an SFP or SFP+ port on a switch, router, or server into a standard RJ45 Ethernet interface. By allowing standard copper cabling (Cat5e/Cat6/Cat6a) to plug directly into modular networking equipment, Copper SFP Transceivers provide a cost-effective and convenient way to extend or adapt network ports for short-range connectivity without changing chassis, optics, or patching infrastructure.

In many environments — enterprise wiring closets, office floors, and adjacent rack connections inside data centers — copper links remain the most practical choice: familiar cabling, low material cost, and simple diagnostics. But Copper SFPs also bring tradeoffs (EMI susceptibility, distance limits, power and latency differences at higher speeds) that must be factored into architecture and procurement choices.

This guide explains how Copper SFPs work (1G and 10G), compares copper SFP modules to fiber SFP modules, outlines installation and troubleshooting best practices, and walks procurement teams through what to verify when buying modules at scale. Where useful, the guide includes practical CLI examples, test methods, and a procurement-ready checklist.

🔴 What is a Copper SFP? (RJ45 SFP Module Overview)

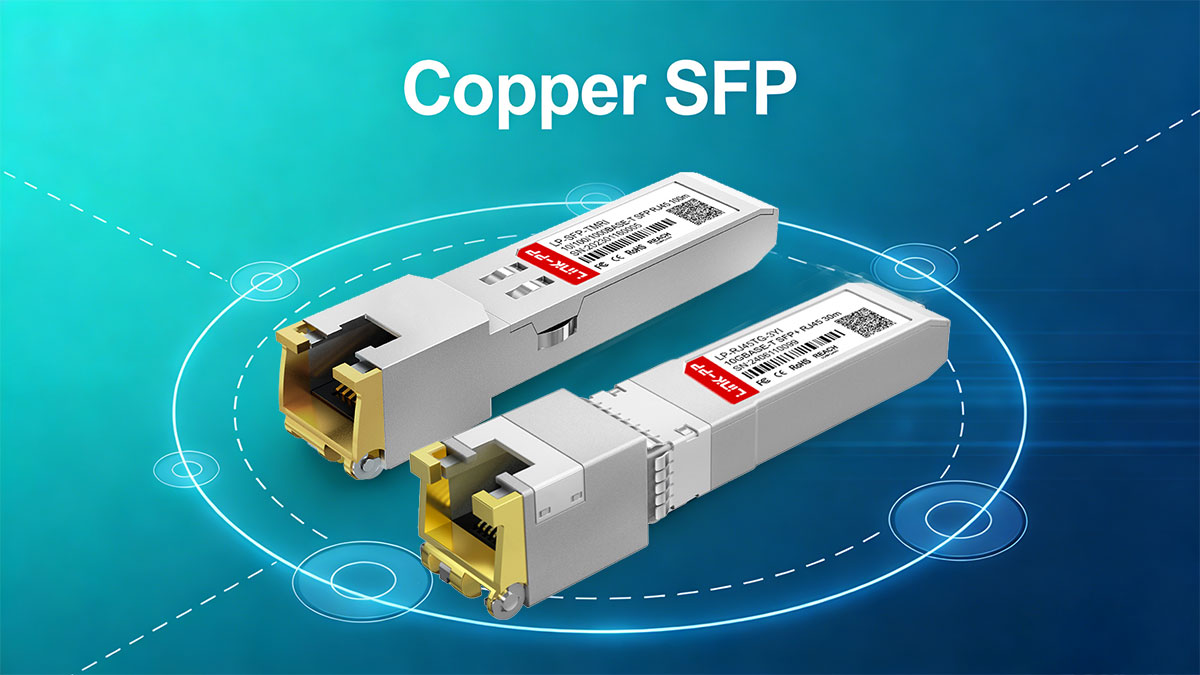

A Copper SFP is an SFP (or SFP+) form-factor transceiver that provides an RJ45 copper Ethernet interface. In effect, it converts the SFP electrical port on a host device into a standard copper Ethernet port that accepts twisted-pair cables (Cat5e/Cat6/Cat6a). These modules are hot-pluggable and follow the same mechanical footprint as SFP fiber transceivers, enabling network operators to mix copper and fiber media on the same switch or device.

Physical & Logical Behavior

-

Form factor: Same mechanical SFP/SFP+ footprint; fits modular ports on switches and routers.

-

Interface: Standard RJ45 female connector (8P8C), accepts patch cables.

-

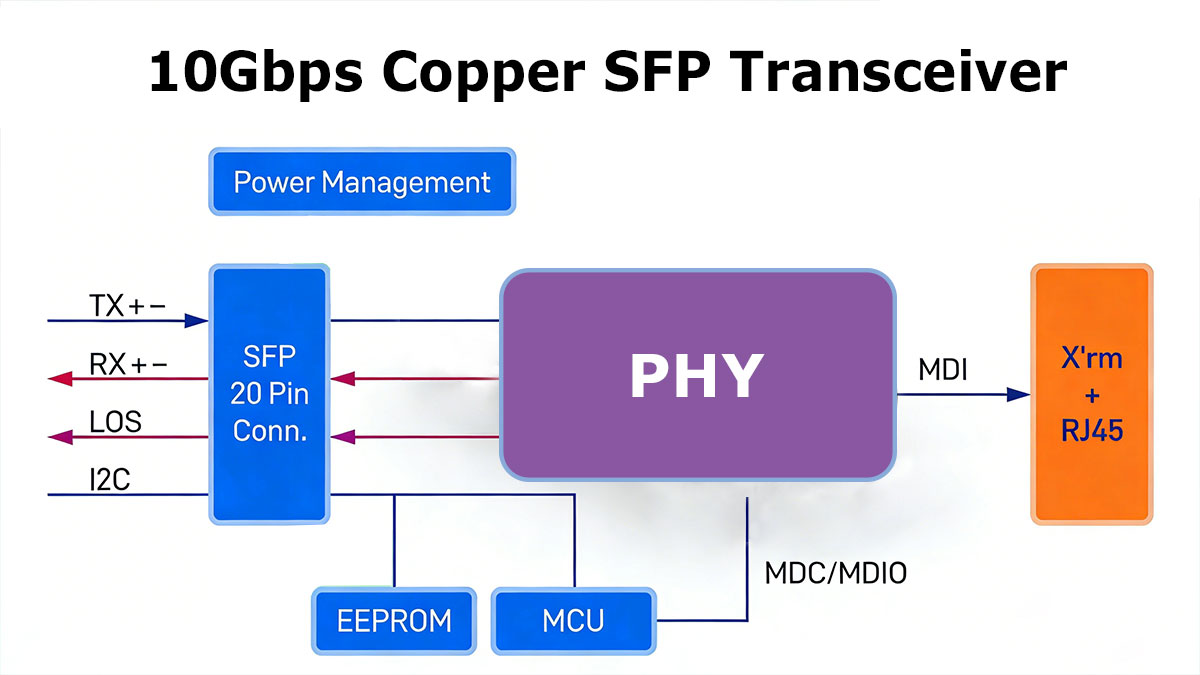

Management: Copper SFPs include EEPROM metadata (vendor, part number, capabilities) accessible by the host device. Unlike optical SFPs, copper modules typically lack true DOM (Digital Optical Monitoring), but they do report link status and EEPROM fields to the switch/OS.

-

Hot-plug: Support hot swapping to replace or add ports without disrupting the chassis.

Common Variants & Speeds

-

1G Copper SFP (1000BASE-T) — supports 1 Gbps over Cat5e/Cat6 up to 100 m.

-

10G Copper SFP+ (10GBASE-T) — supports 10 Gbps; Cat6a for 100 m, Cat6 typically up to ~55 m depending on cable quality and vendor guidance.

-

Multi-rate / Auto-negotiating modules — many RJ45 SFPs support 10/100/1000 or 1G/10G auto-negotiation.

How It Appears to the Host

SFP Copper Modules export EEPROM metadata (vendor, part number, capabilities) to the host. Link status, speed/duplex, and some counters are visible in the switch OS. They do not provide optical DOM telemetry (because they are not optical), but they do reveal PHY stats and link health metrics through the host interface.

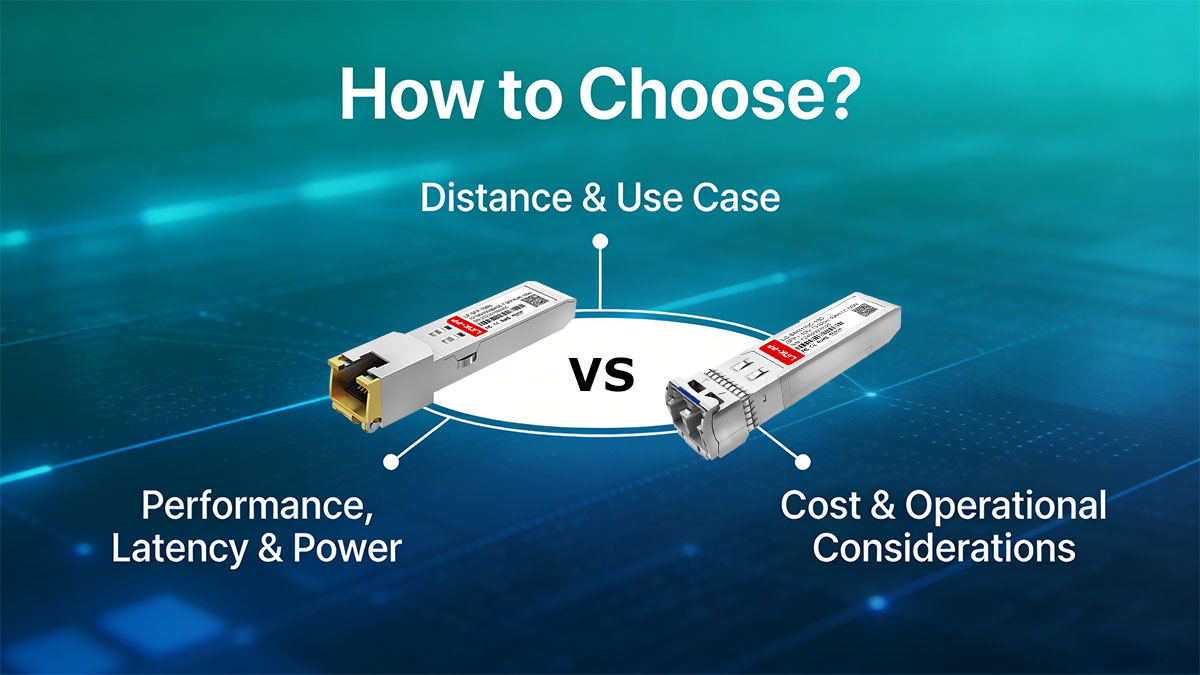

🔴 Copper SFPs vs. Fiber SFPs — How to Choose

Choosing between copper and fiber SFP modules requires balancing distance, cost, performance, electromagnetic interference (EMI), power efficiency, operational complexity, and long-term scalability. The following breakdown and comparison table provide a structured framework for making informed deployment decisions across data centers, enterprise networks, and telecom environments.

Distance & Use Case

-

Copper SFPs: Practical for short links up to 100 m (1G) and up to ~100 m for 10G with Cat6a; commonly used within racks, across adjacent racks, or within a wiring closet.

-

Fiber SFPs: Used for longer distances (hundreds of meters to kilometers) and where electromagnetic immunity or higher speeds/densities are required.

Rule:

Use SFP copper modules where short reach, simplicity, and cost matter.

Use SFP fiber modules where distance, EMI immunity, and future bandwidth scaling are required.

Performance, Latency & Power

Latency: 10GBASE-T (copper) incurs higher PHY latency than optical SFP+ or DACs because of complex encoding, echo-cancellation, and (often) FEC processing. Latency differences are typically microseconds but can matter for latency-sensitive applications (financial trading, high-performance HPC).

Power & Heat: 10G Copper SFP+ modules generally consume more power (often several watts) and generate more heat than optical SFP/SFP+ modules. For high-density deployments, this impacts rack power and cooling.

| Module Type |

Typical Power Draw |

| Fiber SFP (1G) |

0.8 – 1.0 W |

| Copper SFP (1G) |

1.2 – 1.5 W |

| Fiber SFP+ (10G) |

0.9 – 1.5 W |

| Copper SFP+ (10G) |

2.5 – 4.0 W |

Throughput & Error Handling: Under good cabling and environmental conditions, SFP RJ45 modules achieve full line rates. However, cable quality and EMI can cause retransmissions or errors that degrade throughput in practice.

Implications:

-

High-density copper SFP+ deployments require strong airflow design.

-

Copper modules significantly increase rack thermal load.

-

Power constraints may limit port utilization.

Cost & Operational Considerations

-

Cost: Copper optics and copper cabling are often cheaper up front for short runs. But for long-term scaling, fiber may provide better TCO when cabling topology and upgrades are considered.

-

Operational complexity: Copper simplifies patching for small office moves and legacy environments. Fiber reduces risk of EMI and offers better security and future bandwidth headroom.

Rule of thumb: choose copper where short distances, low cost, and RJ45 accessibility matter; choose fiber when distance, EMI immunity, or future bandwidth growth are top priorities.

| Parameter |

Copper SFP (RJ45 SFP Module) |

Fiber SFPs |

| Transmission Medium |

Twisted-pair copper (Cat5e/6/6a) |

Optical fiber |

| Interface |

RJ45 |

LC / SC |

| Typical Speeds |

10/100/1000 Mbps, 10 Gbps |

1G, 10G, 25G, 40G, 100G |

| Max Distance |

100 m |

300 m – 80 km+ |

| Latency |

Medium–High |

Very Low |

| Power Consumption |

High (10G) |

Low |

| EMI Sensitivity |

High |

None |

| Security |

Moderate |

High |

| Installation Ease |

Very easy |

Moderate |

| Scalability |

Limited |

Excellent |

| Cooling Requirement |

High |

Low |

| Best Use Case |

Short-reach access networks |

Core, aggregation, backbone |

| Ideal Buyer |

Enterprise IT, SMEs, campus networks |

Hyperscale DC, ISP, telecom |

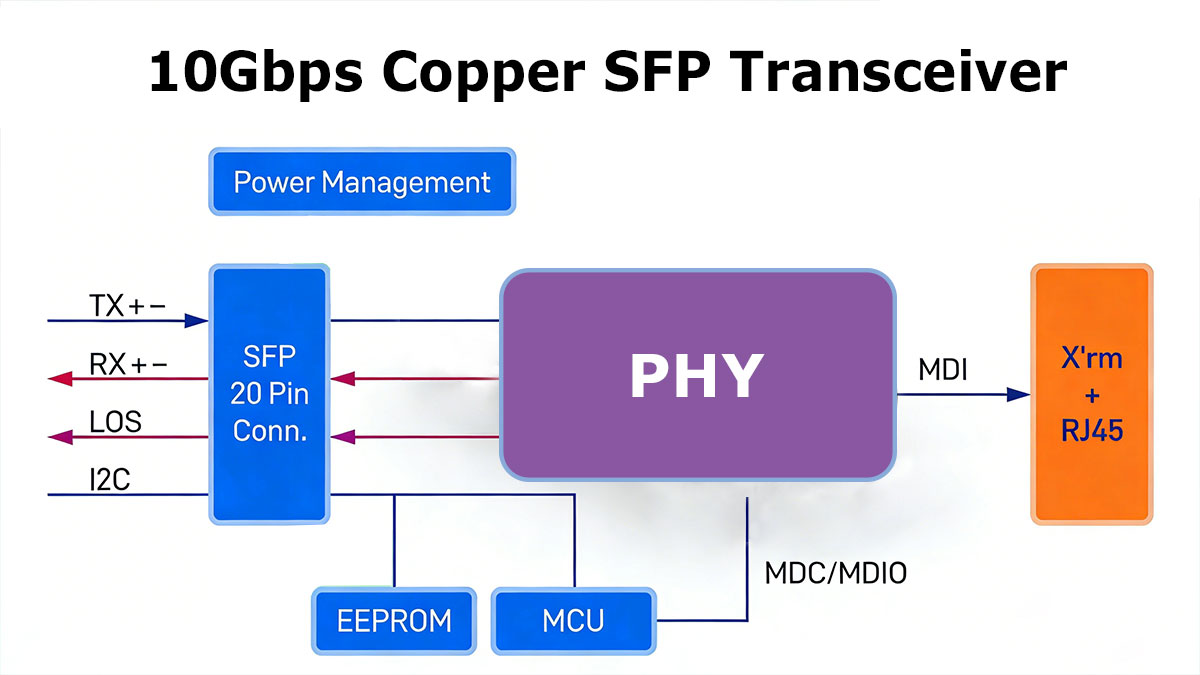

🔴 RJ45 SFP Module: Technical Overview (1G & 10G)

The RJ45 SFP Module, commonly referred to as a Copper SFP, enables modular network equipment to support standard Ethernet cabling by converting an SFP port into a traditional RJ45 interface. This allows switches and routers with SFP slots to leverage existing copper cabling infrastructure while maintaining deployment flexibility.

Understanding the electrical signaling, cabling requirements, power behavior, latency characteristics, and management interfaces of copper SFP modules is essential for reliable operation—especially in enterprise networks, data centers, and telecom access environments.

1G Copper SFP (1000BASE-T)

1000BASE-T uses four twisted pairs and PAM-5 style signaling (IEEE 802.3ab). A 1G Copper SFP will auto-negotiate and run at 1000BASE-T (or a lower speed) over Cat5e/Cat6 cabling. These modules are low power compared to 10GBASE-T and are extremely common for edge/access ports.

-

Cable: Cat5e or Cat6 recommended for full 100 m.

-

Auto-negotiation: 1000BASE-T relies on auto-negotiation and parallel pair signaling; modules interoperate with standard Ethernet ports.

-

Use: Access ports, surveillance, IP phones, short interconnects.

A 1G Copper SFP module auto-negotiates speed and duplex, supporting 10/100/1000 Mbps operation over standard copper Ethernet links.

10G Copper SFP+ (10GBASE-T)

10GBASE-T uses complex PHY functions (IEEE 802.3an) — high-order PAM signaling, echo cancellation, adaptive equalization, and, in many designs, forward error correction and alien crosstalk mitigation. To reach the full 100 m at 10G, Cat6a or better is recommended. Expect higher module power consumption (often 2–4 W per module, vendor dependent), and verify switch thermal headroom for dense installations.

-

Cable: Cat6a to reach 100 m at 10G; Cat6 can do up to ~55 m depending on vendor guidelines; Cat5e is not recommended for 10G.

-

Power & Heat: Significantly higher than 10G optical SFP+; factor in for dense switches.

-

PHY Latency: Higher than optical; check vendor datasheets where latency matters.

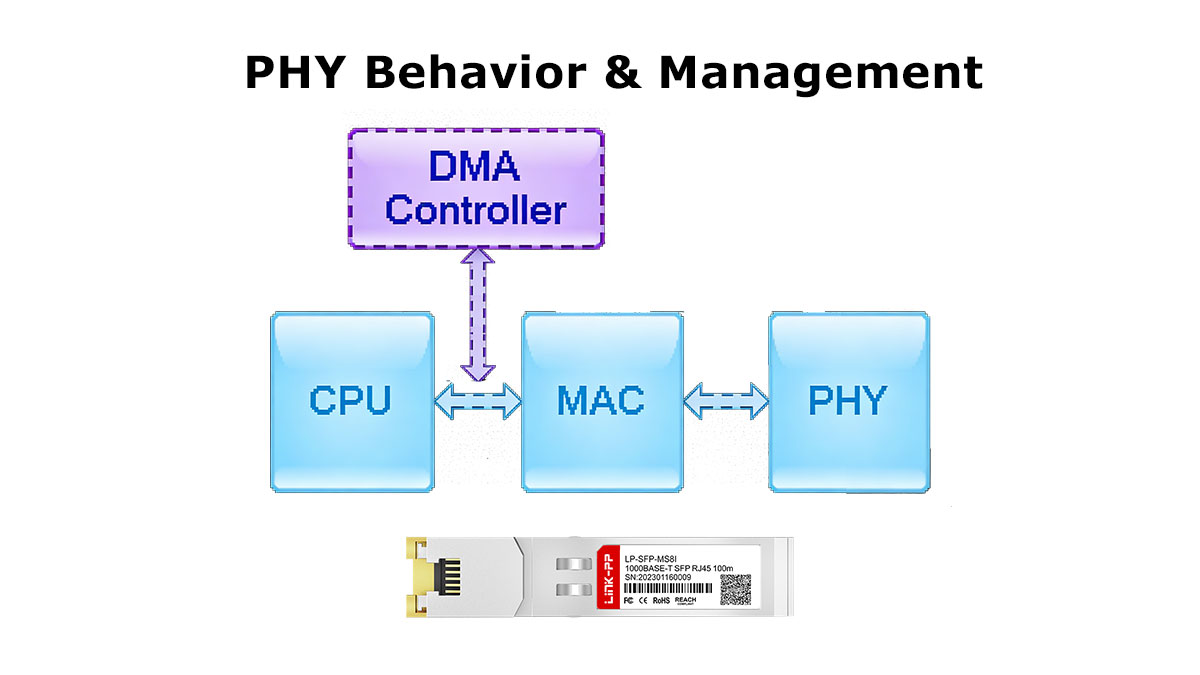

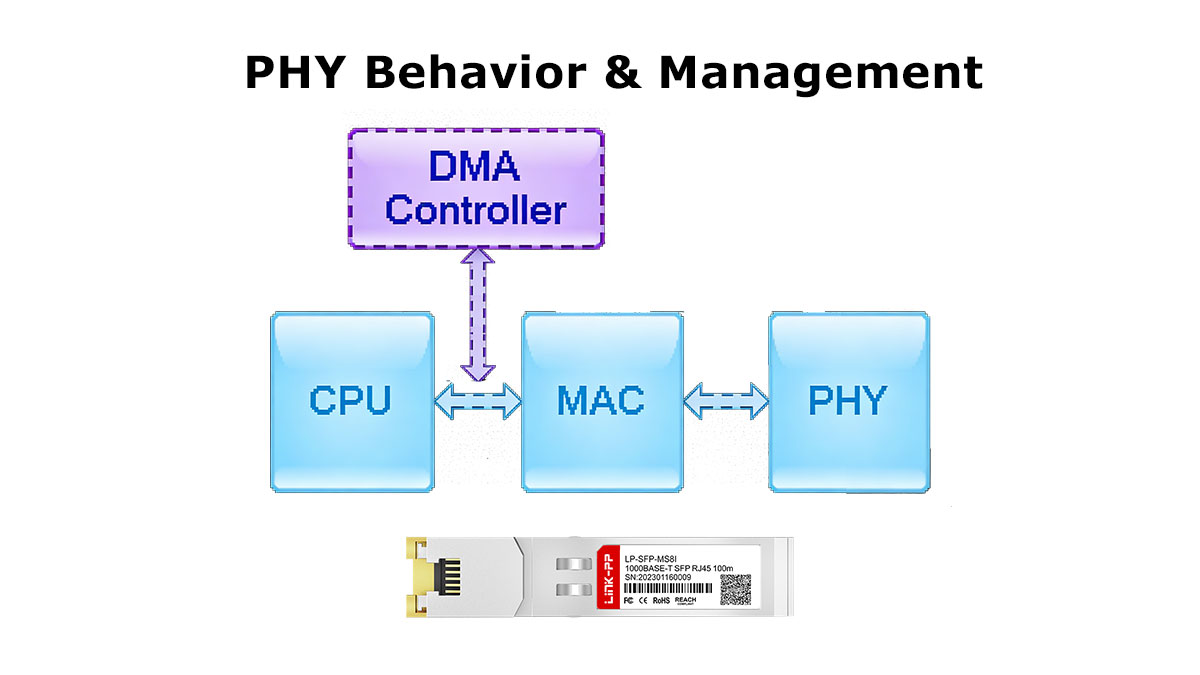

PHY Behavior & Management

Copper SFP modules implement a PHY and present PHY/transceiver EEPROM data to the host. The SFP’s EEPROM includes vendor ID, part number, and supported speeds. Some network platforms enforce vendor whitelisting via EEPROM checks — verify compatibility before purchasing at scale.

Copper SFP modules expose EEPROM data to the host platform, including:

-

Vendor ID

-

Part number

-

Serial number

-

Supported speeds

-

Power class

Some network operating systems apply vendor whitelisting or validation policies, which may restrict the use of third-party modules.

🔴 Use Cases — Where Copper SFPs Make Sense

SFP Copper Modules are far from niche solutions. In modern enterprise and data center environments, they address very practical deployment challenges where cost efficiency, short-distance connectivity, rapid provisioning, and compatibility with existing copper cabling are top priorities.

When used strategically, RJ45 SFP modules provide an optimal balance between operational simplicity, capital expenditure (CapEx) control, and deployment agility, especially in hybrid fiber–copper networks.

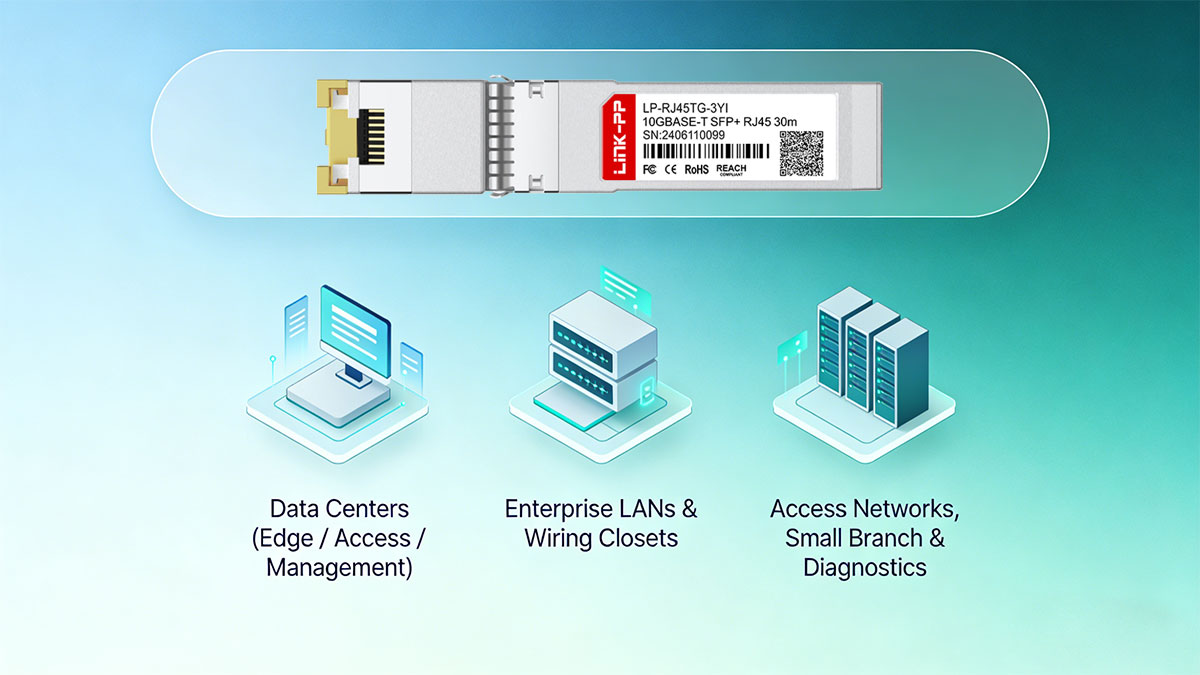

Data Centers (Edge / Access / Management)

Copper SFPs are convenient for management networks, out-of-band (OOB) connections, or connecting legacy devices without requiring fiber patch panels. They are useful for server management, KVM, IPMI, or access-layer switch ports that connect to desktops or office wiring. In data centers, copper SFP modules are rarely used for high-speed backbone links but play a critical supporting role at the access and management layers.

-

Top-of-rack to odd server ports: When servers or legacy devices use copper, a copper SFP avoids extra patching.

-

Management networks / KVM / IPMI: RJ45 SFP modules are convenient for OOB management links that don’t need fiber.

-

Short patch consolidation: Where short cable runs dominate and fiber would overcomplicate.

Enterprise LANs & Wiring Closets

For wiring closets with existing Cat5e/Cat6 infrastructure, copper SFP allows fiber-first switches to accept copper endpoints without rewiring. They reduce deployment friction for office moves and patch changes and lower immediate capex.

Enterprise campus networks are where SFP Copper delivers the strongest ROI. Most office buildings already contain extensive Cat5e/Cat6 cabling infrastructure, making RJ45 SFP module a natural fit

-

Floor wiring to switches: Add RJ45 ports to fiber-centric switches in wiring closets.

-

Cost-sensitive edge access: Offices with existing Cat5e/Cat6 infrastructure can utilize Copper SFP modules for economical port density.

Access Networks, Small Branch & Diagnostics

Copper SFPs shine where a temporary or diagnostic link is needed — plug in an RJ45 patch and you have immediate connectivity without an optical transceiver inventory or fiber patching.

-

Small branch offices: Copper SFP transceivers work with local copper cabling and simplify provisioning.

-

Troubleshooting & temporary links: Rapidly patch copper cable to a modular port without fiber splicing or transceivers.

Engineering Rule-of-Thumb

Deploy Copper SFPs when:

-

Distance ≤ 100 m

-

Existing copper cabling dominates

-

Operational simplicity is critical

-

Cost efficiency outweighs long-term fiber scalability

Prefer Fiber SFPs when:

Quick Selection Guide – How to Choose the Right RJ45 SFP Module

| Scenario |

Recommended Module |

Cable |

Distance |

Notes |

| Office wiring |

1G Copper SFP |

Cat5e |

≤100m |

Lowest cost |

| Data center OOB |

1G Copper SFP |

Cat6 |

≤100m |

Stable mgmt |

| TOR to legacy server |

10G Copper SFP+ |

Cat6a |

≤30–100m |

Power check |

| Low latency |

Fiber SFP+ |

Fiber |

300m+ |

Avoid copper |

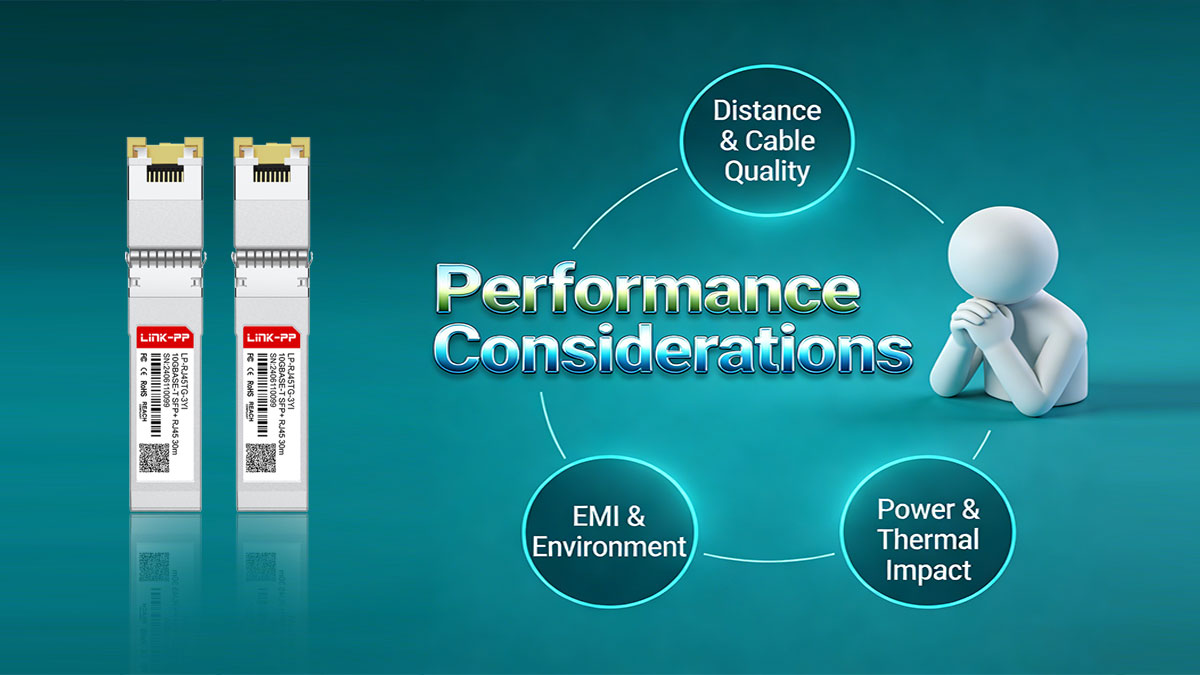

🔴 Performance Considerations — Distance, EMI, Power, Latency

When deploying Copper SFPs or RJ45 SFP Modules, performance evaluation must be methodical and engineering-driven. While datasheets provide theoretical limits, real-world outcomes are dominated by cable quality, electromagnetic interference (EMI), installation discipline, and environmental conditions.

Ignoring these factors often results in intermittent errors, unexpected link drops, excessive retransmissions, and thermal instability, particularly at 10G speeds.

1. Distance & Cable Quality

-

1G: Cat5e/Cat6 will typically support 100 m reliably.

-

10G: Cat6a rated for 100 m; Cat6 may achieve ~55 m depending on cable quality and installation. For 10G over copper, always validate cable plants with a cable certifier.

Tip: Always validate cable plants with a cable certifier when deploying 10G copper links.

2. EMI & Environment

Copper links are vulnerable to electromagnetic interference (EMI). Avoid running cables near large motors, power switching equipment, or unshielded power runs. Where EMI is significant or security of the medium is a concern, prefer fiber. If the environment has significant EMI, choose fiber to avoid intermittent errors and packet loss.

3. Power & Thermal Impact

10G Copper SFP consume significantly more power than equivalent optical SFPs. For dense port counts, factor additional watts per port into rack power and cooling planning.

When selecting RJ45 10G SFPs, calculate per-port power and aggregate for the switch. Dense blade or top-of-rack switches can require significant cooling provisions if many 10GBASE-T modules are used.

4. Latency Considerations

10GBASE-T PHY processing can add microseconds of latency versus optical SFP+ or passive DACs. For most enterprise applications, copper SFP latency is negligible; for microsecond-sensitive applications (HFT, specialized HPC, ultra-low latency trading), optical or direct-attach DAC alternatives often perform better.

Performance Decision Matrix

| Parameter |

Copper SFP |

Fiber SFP |

| Max distance |

≤ 100 m |

Up to 160 km |

| EMI immunity |

❌ Low |

✅ Complete |

| Power efficiency |

❌ Lower |

✅ Higher |

| Thermal density |

❌ Higher |

✅ Lower |

| Latency |

❌ Higher |

✅ Lower |

| Deployment simplicity |

✅ High |

❌ Medium |

| Infrastructure reuse |

✅ Excellent |

❌ Limited |

🔴 Deployment, Compatibility & Troubleshooting Guide for Copper SFPs

A systematic deployment and troubleshooting framework minimizes downtime, improves network stability, and reduces operational risk.

♦ Pre-Deployment Compatibility & Readiness Checks

-

Verify switch compatibility

Check the switch vendor’s qualified transceiver list or test a sample module. Some vendors block non-OEM modules via EEPROM authentication.

-

Cabling verification

For 10G copper deployments, certified Cat6a cabling is required for full 100-meter reach.

-

Power & thermal planning

Confirm sufficient chassis airflow and power headroom to support higher PHY power dissipation.

♦ Physical Installation & Configuration Best Practices

-

Inspect module and SFP cage for debris or contamination

-

Insert Copper SFP until fully seated and lock the latch

-

Connect RJ45 cable and label both ends clearly

-

Monitor port LEDs and switch logs to verify correct speed and duplex negotiation

♦ EEPROM Behavior, Host Recognition & Vendor Locking

Copper SFPs expose EEPROM data including vendor ID, part number, serial number, and supported link modes.

Some switch vendors enforce vendor locking through EEPROM verification. If a third-party module is rejected:

-

Verify firmware compatibility

-

Consult vendor policy documentation

-

Select compatibility-validated suppliers such as LINK-PP RJ45 SFP Modules, which provide documented multi-vendor interoperability testing.

♦ Common Fault Scenarios & Quick Diagnostics

-

No link light → Check seating, swap cable/module, verify remote port status

-

Link up but low speed → Verify auto-negotiation, duplex settings, cable grade

-

Intermittent drops → Test for EMI, cable shielding, connector integrity

♦ Testing Tools & Operational Monitoring

-

Cable certification tester — attenuation, NEXT, return loss, skew

-

Switch CLI diagnostics — CRC errors, FCS errors, packet drops

-

Loopback testing — isolate module vs cabling faults

-

Traffic stress testing — iperf throughput + BER behavior

♦ When to Escalate to Vendor Support

Escalate when:

-

-

Reproducible link instability persists after module and cable replacement

-

Firmware-level transceiver rejection occurs

-

Certified cabling still fails 10G performance validation

🔴 Procurement & Vendor Considerations

Selecting Copper SFPs is not purely a technical decision — it is also a strategic procurement process involving compatibility risk, supply-chain reliability, lifecycle management, and total cost of ownership (TCO).

A structured vendor evaluation framework ensures network stability, procurement predictability, and long-term operational confidence.

Technical Criteria

-

Form-factor & MSA compliance: Ensure modules conform to SFP/SFP+ mechanical standards.

-

Electrical & PHY compliance: Verify support for 1000BASE-T or 10GBASE-T protocols.

-

Datasheet parameters: Check supported cable categories, power consumption, operating temperature, and latency if provided.

-

Compatibility verification: Test modules on target switch platforms before mass purchase.

Commercial & Lifecycle Criteria

-

Warranty & RMA: Look for clear replacement policies and lead time guarantees.

-

Supply stability: Prioritize vendors with predictable lead times to avoid project delays.

-

Security & provenance: Confirm components are genuine, not counterfeit.

Third-Party & OEM Considerations

Many organizations opt for trusted third-party vendors to reduce costs without sacrificing compliance. LINK-PP 1G/10G Copper modules are one example of MSA-compliant third-party SFP modules that provide documented interoperability and vendor support in enterprise and telco environments. When buying OEM modules:

-

Request interoperability test records or references.

-

Purchase small pilot quantities for field testing.

-

Confirm vendor will support firmware/compatibility issues if they arise.

🔴 Standards, PHY Behavior & Cable Quality (Deep Dive)

Relevant Standards

-

IEEE 802.3ab (1000BASE-T) — Gigabit Ethernet over copper.

-

IEEE 802.3an (10GBASE-T) — 10 Gigabit Ethernet over copper with stringent channel and AXT requirements.

-

TIA/EIA-568, ISO/IEC 11801 — structured cabling and channel categories (Cat5e, Cat6, Cat6a, etc.).

PHY Implementation Notes

Copper SFP modules embed PHY silicon (from vendors like Broadcom, Marvell, Aquantia, etc.). PHY choice impacts latency, power consumption, and interoperability. At 10G, PHYs implement adaptive equalization, hybrid echo cancellation, and AXT mitigation; mismatches between PHY implementations can show as intermittent link failures where cabling sit at the margin.

What to Measure in Cabling Certification

-

Insertion loss (attenuation) at the relevant frequencies.

-

Near-End Crosstalk (NEXT) and Far-End Crosstalk (FEXT).

-

Alien Crosstalk (AXT) for high-density runs.

-

Return Loss and pair skew.

A certified cabling test is mandatory for reliable 10G operation.

🔴FAQs about Copper SFPs

Q: What is a copper SFP?

A: A copper SFP is a Small Form-factor Pluggable transceiver that provides an RJ45 copper Ethernet interface, allowing standard twisted-pair cables to connect to SFP or SFP+ ports. Copper SFPs support speeds such as 1G (1000BASE-T) and 10G (10GBASE-T) for short-range links.

Q: What is the difference between copper SFP and fiber SFP?

A: Copper SFP Modules use copper twisted-pair cables and are suited for short distances (up to 100 m), are susceptible to EMI, and generally cost less for short runs. Fiber SFPs use optical fiber for longer distances, immunity to EMI, and usually lower latency and power for high speeds. Choice depends on distance, environment, and performance needs.

Q: Does SFP support copper?

A: Yes. SFP and SFP+ are form factors that can host either optical transceivers or copper RJ45 SFP modules. The host port must accept the specific module type and be compatible with the module’s electrical characteristics.

Q: What does SFP stand for?

A: SFP stands for Small Form-factor Pluggable, a hot-pluggable transceiver standard used for both optical and copper network links.

Q: Can 10G run over Cat6 cable?

A: 10GBASE-T can run over Cat6 cable but typically only up to ~55 m depending on cable quality and installation; Cat6a is recommended for reliable 100 m reach.

Q: Do copper SFPs use DOM?

A: Copper SFPs do not support optical DOM because DOM measures optical parameters. However, they still expose EEPROM fields and link status via the host switch.

🔴Conclusion & Practical Takeaways

Copper SFPs (RJ45 SFP Modules) are a practical, economical option for short-range Ethernet links where existing copper infrastructure is present or where simplicity and cost savings are priorities. They excel for access ports, wiring closets, management networks, and rapid temporary or diagnostic links. For 1G deployments they are an especially economical choice; for 10G, they remain viable when certified Cat6a cabling is available and when power/latency tradeoffs are acceptable.

When to choose Copper SFPs:

-

Short distances (≤100 m) with certified copper cabling.

-

Environments without severe EMI.

-

Situations where RJ45 physical access is required (e.g., temporary connections, desk wiring).

-

Cost-sensitive edge/access deployments.

When to prefer Fiber SFPs:

For enterprise and carrier buyers seeking reliable MSA-compliant copper transceivers, consider third-party vendors with strong interoperability testing and support. LINK-PP Copper SFPs offer MSA-compliant RJ45 modules designed for enterprise and telecom deployments, with documented compatibility and supply stability — useful when you need flexible sourcing beyond OEM optics.

👉 Explore certified Copper SFP modules at the LINK-PP Official Store

Stable supply · Verified compatibility · Enterprise-grade quality

Glossary & Quick Reference Chart

| Term |

Short Definition |

| SFP |

Small Form-factor Pluggable transceiver (optical or copper). |

| RJ45 SFP Module |

A copper SFP providing an RJ45 port for twisted-pair Ethernet. |

| 1000BASE-T |

Gigabit Ethernet over twisted-pair copper (1 Gbps). |

| 10GBASE-T |

10 Gigabit Ethernet over twisted-pair copper (10 Gbps). |

| Cat5e / Cat6 / Cat6a |

Cable category ratings; Cat6a recommended for 10G up to 100 m. |

| MDI/MDIX |

Media Dependent Interface — auto crossover capability on Ethernet ports. |

| EEPROM |

Module memory containing vendor and capability information. |

| DOM / DDM |

Digital Optical Monitoring — optical module telemetry (not applicable for copper). |

| MSA |

Multi-Source Agreement — mechanical/electrical standard ensuring interoperability. |

| EMI |

Electromagnetic Interference — can affect copper signal integrity. |

| DAC |

Direct Attach Copper — passive or active twinax cables for short 10G/40G links. |

Practical Deployment Checklist

-

Validate module compatibility with exact switch model and firmware.

-

Certify cabling for 10G links (Cat6a for 100 m).

-

Confirm power and cooling headroom for copper PHY heat.

-

Install module, connect cable, and label both ends.

-

Run validation traffic tests (iperf/netperf) and monitor counters.

-

Document port assignments and keep spares for rapid replacement.

Appendix — Author & Version Information

Author: LINK-PP Technical Content Team — Practical network engineering guidance for enterprise and carrier deployments.

Last updated: Jan 2026.

Notes: This article is intended for technical readers and procurement teams. Always validate specific module compatibility with target switch vendors and firmware before large-scale procurement.