MSA (Multi-Source Agreement) standards define the mechanical, electrical, and management interfaces of optical transceivers, enabling multi-vendor interoperability, supply chain flexibility, and large-scale network deployment. Understanding MSA is critical for compatibility validation, cost optimization, and long-term network reliability.

In high-speed fiber networks, MSA standards are the invisible framework that makes interoperability, scalability, and cost efficiency possible. From SFP and QSFP to today’s QSFP-DD and OSFP form factors, MSA specifications define how optical modules are mechanically, electrically, and logically designed—ensuring that products from different vendors can work together reliably.

In this guide, we’ll explain what MSA standards are, why they exist, and how they shape optical transceiver design, while sharing real-world engineering insights on compatibility risks, procurement traps, and deployment best practices.

What you will learn:

-

What MSA standards are and why they were created

-

How MSA defines optical module form factors and interfaces

-

Key SFP, QSFP, and QSFP-DD MSA specifications

-

Common compatibility and procurement pitfalls

-

Engineering deployment best practices based on real field experience

This article is written for network engineers and data center architects who need accurate, actionable guidance—not just theoretical definitions.

📘 What Are MSA Standards?

Multi-Source Agreement (MSA) standards are industry-driven technical specifications jointly developed by multiple leading manufacturers to define common form factors, electrical interfaces, optical interfaces, mechanical dimensions, and management protocols for optical transceiver modules.

In simple terms, MSA standards ensure that optical modules from different vendors can be physically compatible, electrically interoperable, and operationally consistent across network equipment platforms.

Unlike formal standards issued by organizations such as IEEE, ITU-T, or TIA, MSAs are vendor-initiated, market-driven agreements. They are created to accelerate innovation, reduce integration complexity, and eliminate vendor lock-in, especially in fast-evolving optical networking environments.

Core Objectives of MSA Standards

MSA standards are designed to solve several critical industry challenges:

-

Interoperability: Enable optical modules from different manufacturers to function correctly in the same switch or router platform.

-

Mechanical Compatibility: Standardize module dimensions, connector placement, cage design, and thermal profiles.

-

Electrical Consistency: Define pin assignments, signaling levels, control logic, and power requirements.

-

Management & Monitoring: Specify Digital Optical Monitoring (DOM/DDM) functions for real-time diagnostics.

-

Supply Chain Stability: Promote multi-vendor sourcing, reducing procurement risk and supply disruption.

Together, these objectives create a hardware abstraction layer for optical transceivers, allowing network operators to deploy, replace, and scale optical links without being locked into a single vendor ecosystem.

Why MSA Standards Exist: The Industry Problem They Solve

Before the widespread adoption of MSAs, optical transceiver designs were often vendor-proprietary, leading to:

-

Fragmented module form factors

-

Inconsistent electrical pin definitions

-

Limited cross-vendor compatibility

-

High replacement cost

-

Strong vendor lock-in

This created significant challenges for data center operators, telecom carriers, and system integrators, particularly in environments requiring:

MSA standards emerged as a collaborative solution — enabling open, interoperable, and standardized optical module ecosystems, dramatically improving deployment flexibility and long-term network economics.

MSA vs IEEE vs ITU-T: Understanding the Differences

| Standard Body |

Primary Focus |

Scope |

| MSA |

Module hardware & electrical interface |

Mechanical form, pinouts, power, management |

| IEEE 802.3 |

Ethernet protocols & PHY layers |

Line rate, encoding, optical specs |

| ITU-T |

Telecom transport standards |

Carrier-grade optical networking |

| TIA / ANSI |

Cabling & infrastructure |

Fiber & connector standards |

Key distinction:

IEEE and ITU-T define how data is transmitted, while MSAs define how transceiver modules are physically built and electrically integrated into network equipment.

This division of responsibility allows:

Technical Scope of MSA Standards

A typical optical transceiver MSA specification covers:

-

Mechanical envelope and cage dimensions

-

Electrical pin definition and logic control

-

Power supply and thermal limits

-

Optical connector interface (LC, MPO, etc.)

-

Digital Diagnostic Monitoring (DDM/DOM) registers

-

EEPROM memory map and vendor identification fields

These definitions form the foundation for standardized transceiver ecosystems, enabling consistent module behavior across switches, routers, servers, and transport platforms.

Industry Impact of MSA Adoption

Today, nearly all mainstream optical modules — including SFP, SFP+, SFP28, QSFP+, QSFP28, QSFP-DD, OSFP — are MSA-based form factors.

As a result:

-

Data center operators can deploy multi-vendor optical strategies

-

Equipment manufacturers can focus innovation on performance rather than mechanical redesign

-

Procurement teams gain cost leverage and supply resilience

-

Engineers benefit from predictable integration and diagnostics behavior

This makes MSA standards one of the most critical yet often overlooked pillars of modern optical networking infrastructure.

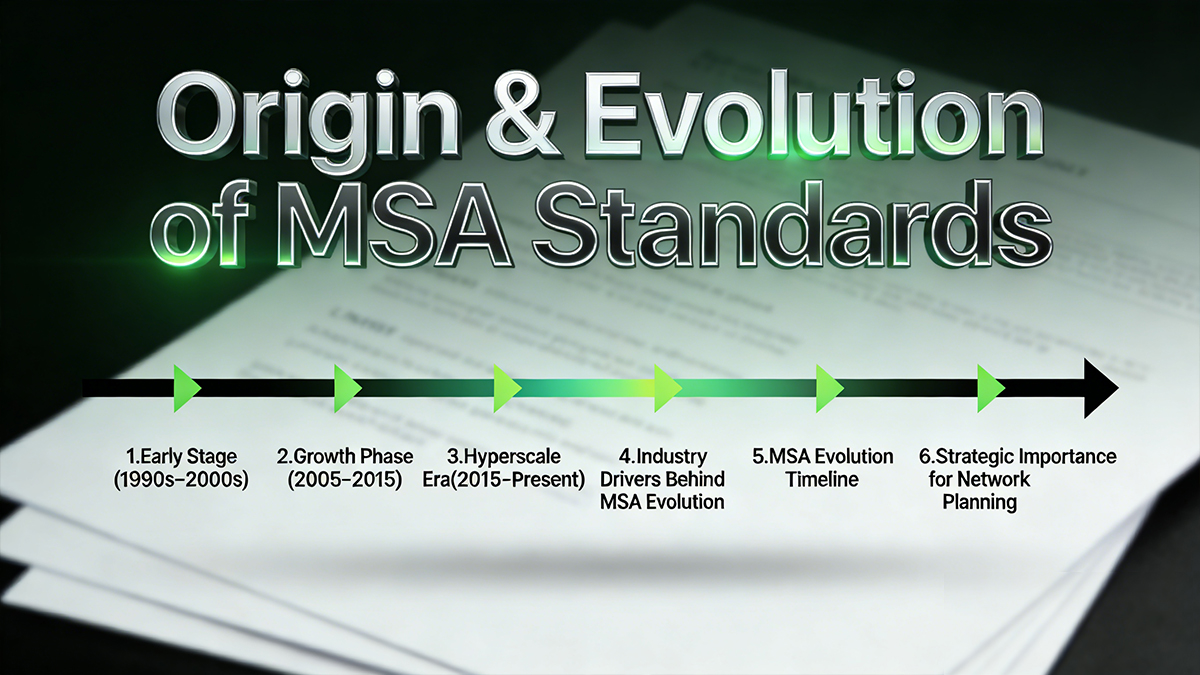

📘 Origin & Evolution of MSA Standards

The evolution of Multi-Source Agreement (MSA) standards is tightly coupled with the growth of Ethernet speeds, optical networking scale, and hyperscale data center expansion. MSA frameworks did not emerge by accident — they were created as a direct industry response to fragmentation, vendor lock-in, and rapid technology iteration.

Understanding the origin and evolution of MSAs helps engineers, architects, and procurement teams predict future module trends and make forward-compatible infrastructure decisions.

Early Stage: From Proprietary Optics to Multi-Vendor Interoperability (1990s–2000s)

In the early era of fiber-optic networking, transceiver modules were mostly proprietary, tightly bound to specific network equipment vendors. Each vendor used its own:

This resulted in:

As Ethernet speeds accelerated from Fast Ethernet (100 Mb/s) to Gigabit Ethernet (1 Gb/s), the industry urgently needed standardized pluggable optical modules that could scale economically.

This demand led to the birth of early MSAs such as:

These early MSAs established the fundamental model of vendor-neutral transceiver interoperability, setting the foundation for modern pluggable optics.

Growth Phase: Standardization Driven by Bandwidth Explosion (2005–2015)

Between 2005 and 2015, explosive growth in:

-

Cloud computing

-

Web-scale data centers

-

Mobile broadband

-

Enterprise networking

pushed Ethernet speeds from 1G → 10G → 40G → 100G.

This acceleration created three core engineering challenges:

-

Port density pressure — more bandwidth per rack unit

-

Thermal constraints — power density became a limiting factor

-

Signal integrity complexity — higher speeds required tighter electrical and optical specifications

To address these issues, the industry collaboratively launched a series of high-impact MSAs, including:

| Generation |

Key MSAs |

Primary Goal |

| 10G Era |

SFP+, XFP |

Higher port density, lower power |

| 40G Era |

QSFP+, CFP |

Parallel optics, space optimization |

| 100G Era |

QSFP28, CFP2, CFP4 |

Compact high-speed pluggables |

Among these, 40G QSFP+ and 100G QSFP28 became dominant, driven by superior power efficiency, density, and scalability.

Hyperscale Era: Open Ecosystems & Rapid Innovation (2015–Present)

From 2015 onward, hyperscale data centers, AI clusters, and 5G infrastructure became the dominant force shaping optical module design.

This period introduced new drivers:

-

Ultra-high port density (400G → 800G → 1.6T)

-

Strict power envelopes per port

-

Fast deployment cycles

-

Open, multi-vendor sourcing strategies

In response, the industry developed next-generation MSA frameworks, including:

-

QSFP-DD MSA (Double Density)

-

OSFP MSA (Octal Small Form-factor Pluggable)

-

COBO MSA (On-board optics)

These MSAs focus on:

-

Electrical interfaces up to 112 Gbaud PAM4

-

Advanced thermal management

-

Mechanical designs optimized for high-airflow environments

-

Scalable architectures for 800G+ Ethernet

Industry Drivers Behind MSA Evolution

The continuous evolution of MSA standards is powered by five fundamental industry forces:

-

Bandwidth Demand Growth

AI, cloud computing, and 5G drive exponential bandwidth needs.

-

Port Density Optimization

Rack-level density directly impacts data center cost and power efficiency.

-

Thermal Engineering Constraints

Power budgets increasingly limit transceiver form factor feasibility.

-

Supply Chain Resilience

Multi-source availability reduces procurement risk and price volatility.

-

Open Networking Philosophy

Hyperscalers demand vendor-neutral hardware ecosystems.

Together, these forces push MSAs to evolve faster than traditional standards bodies, allowing the industry to rapidly adapt to market needs.

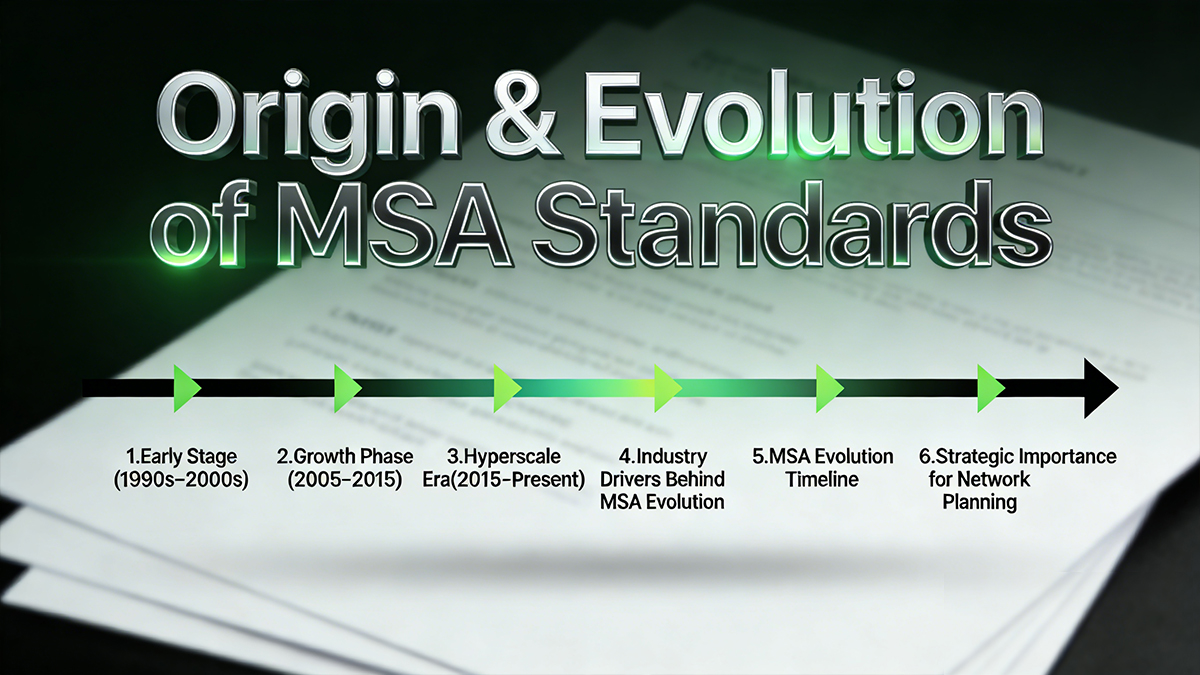

MSA Evolution Timeline (Key Milestones)

| Year |

Milestone |

Impact |

| 1999–2000 |

GBIC MSA |

First standardized pluggable optics |

| 2001–2003 |

SFP MSA |

Compact form factor, mass adoption |

| 2006–2008 |

SFP+ MSA |

10G density breakthrough |

| 2010–2012 |

QSFP+ MSA |

40G parallel optics era |

| 2014–2016 |

QSFP28 MSA |

100G mainstream adoption |

| 2018–2020 |

QSFP-DD & OSFP MSA |

400G infrastructure readiness |

| 2023–Present |

800G MSA frameworks |

AI-driven network scaling |

This timeline illustrates how MSAs consistently precede large-scale commercial deployment, enabling rapid industry transitions.

Strategic Importance for Network Planning

For system architects and procurement leaders, understanding MSA evolution is critical to:

-

Predict technology roadmaps

-

Avoid premature infrastructure obsolescence

-

Design forward-compatible fiber plant architectures

-

Optimize long-term capital investment strategies

In modern network design, choosing the right MSA roadmap is as important as choosing the right optical standard.

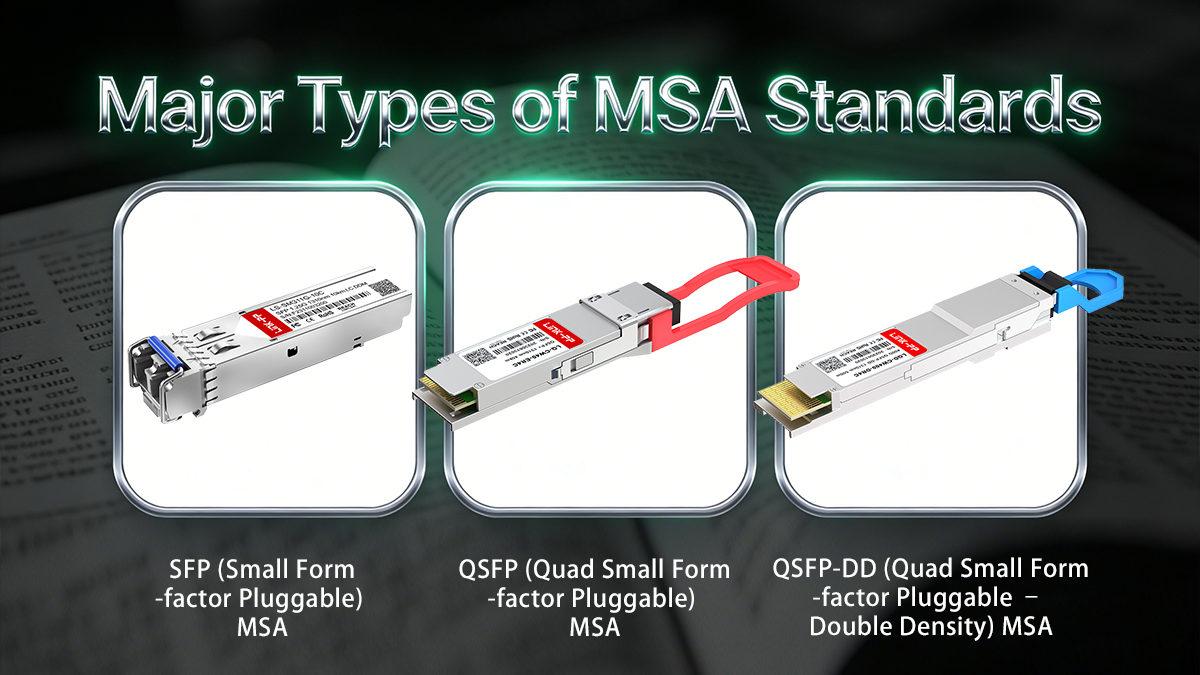

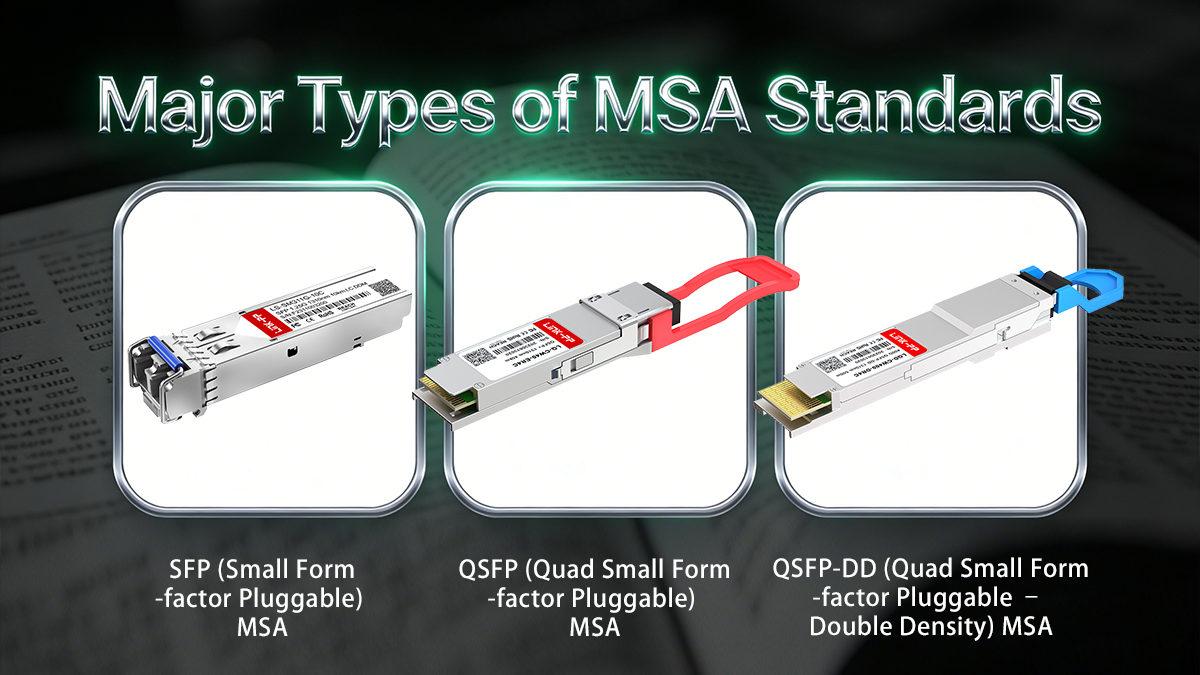

📘 Major Types of MSA Standards (SFP, QSFP, QSFP-DD, OSFP & Beyond)

Multi-Source Agreements (MSAs) define standardized mechanical, electrical, and optical interfaces for pluggable modules, ensuring multi-vendor interoperability and simplifying network deployment. Understanding the main MSA types is critical for engineers, architects, and procurement teams when designing scalable, high-performance optical networks.

1. SFP (Small Form-factor Pluggable) MSA

-

Speed & Use Case: Up to 10 Gbps per lane; widely used for 1G–10G links in enterprise, campus, and industrial networks.

-

Form Factor: Compact, single-lane transceiver.

-

Standards & MSAs: SFP MSA, SFP+ MSA (SFF-8431 / SFF-8432), SFP28 (25G).

-

Key Features:

-

Deployment Notes: Ideal for constrained rack space, low-power scenarios, and short- to medium-distance multimode or single-mode fiber.

2. QSFP (Quad Small Form-factor Pluggable) MSA

-

Speed & Use Case: Aggregated 4×10 Gbps (QSFP+), 4×25 Gbps (QSFP28), mainly for leaf-spine, aggregation, and core data center links.

-

Form Factor: Quad-lane module; high port density per rack unit.

-

Standards & MSAs: QSFP+ MSA (SFF-8436 / SFF-8636), QSFP28 MSA.

-

Key Features:

-

Parallel optics (SR4/LR4)

-

Hot-swappable with DOM/DDM support

-

Moderate power consumption (1.5–5.5 W typical)

-

Deployment Notes: Enables breakout cables (e.g., one 100G port splitting into four 25G SFP28 links) for flexible architecture.

3. QSFP-DD (Quad Small Form-factor Pluggable – Double Density) MSA

-

Speed & Use Case: 200G–400G+ per port, designed for hyperscale data centers and high-speed backbone networks.

-

Form Factor: Double-density QSFP; 8 electrical lanes with PAM4 modulation support.

-

Standards & MSAs: QSFP-DD MSA (SFF-8679 / SFF-8665).

-

Key Features:

-

Coherent & non-coherent options

-

Enhanced thermal design for 8–22 W power modules

-

DOM/DDM monitoring for optical power, temperature, and voltage

-

Deployment Notes: Requires advanced cooling planning; ensures BER ≤1×10⁻¹² in parallel optics deployments.

4. OSFP (Octal Small Form-factor Pluggable) MSA

-

Speed & Use Case: 400G–1.6T per port, emerging in next-generation hyperscale and AI cluster networks.

-

Form Factor: Eight-lane module; wider than QSFP-DD for higher power and thermal tolerance.

-

Standards & MSAs: OSFP MSA (pending SFF drafts).

-

Key Features:

-

Deployment Notes: Targets ultra-high port density racks; compatible with future 800G+ infrastructures.

5. Specialized & Emerging MSAs

-

COBO (Component on Board) MSA: Pluggable but directly mounted on switch board, reducing electrical loss.

-

CFP / CFP2 / CFP4: Early high-speed 100G–400G optics; large form factors mainly for long-haul or metro networks.

-

Future Trends:

6. Summary Table: Key MSA Types & Applications

| MSA Type |

Max Speed |

Form Factor |

Typical Use Case |

Power |

DOM/DDM |

| SFP / SFP+ |

10–25G |

Single-lane |

Enterprise, Industrial |

<1.5 W |

Yes |

| QSFP+ / QSFP28 |

40–100G |

Quad-lane |

Data center leaf/spine |

1.5–5.5 W |

Yes |

| QSFP-DD |

200–400G+ |

8-lane / double density |

Hyperscale core |

8–22 W |

Yes |

| OSFP |

400G–1.6T |

8-lane wide |

Next-gen AI / HPC |

15–25 W |

Yes |

| CFP / CFP2 / CFP4 |

100–400G |

Large pluggable |

Metro / long-haul |

15–25 W |

Yes |

✅ Key Takeaways:

-

MSA standards ensure multi-vendor interoperability, reduce procurement risk, and simplify network operations.

-

Choice of MSA depends on speed, form factor, thermal budget, and deployment topology.

-

Emerging MSAs like QSFP-DD and OSFP prepare networks for 800G+ Ethernet and AI workloads.

-

Compliance with MSA frameworks allows predictable link budget, DOM monitoring, and BER reliability, crucial for hyperscale and enterprise environments.

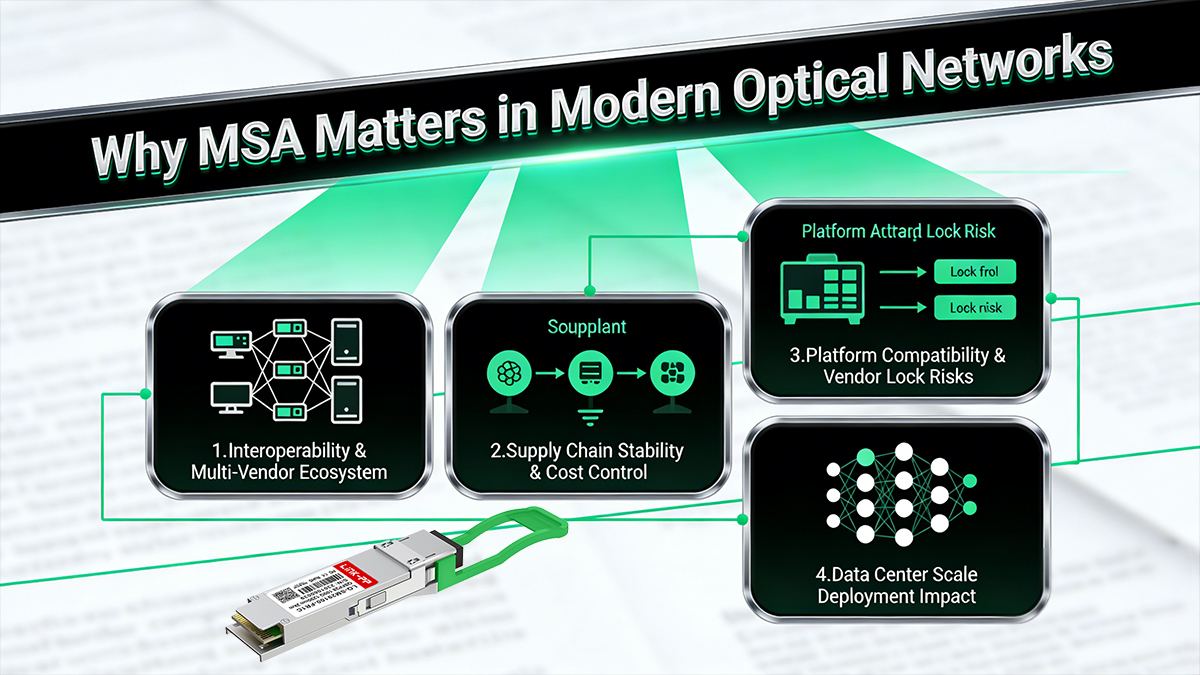

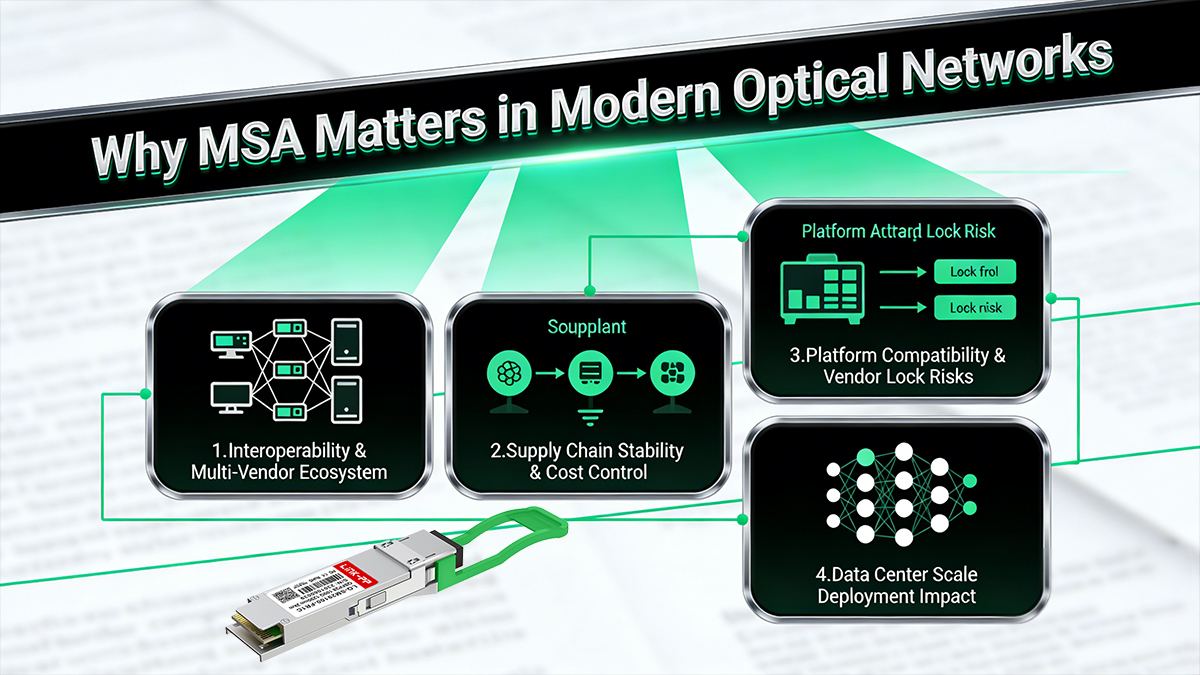

📘 Why MSA Matters in Modern Optical Networks

Multi-Source Agreements (MSAs) are more than just technical specifications — they are the backbone of scalable, reliable, and cost-effective optical networks. By standardizing mechanical, electrical, and optical interfaces, MSAs enable predictable performance across vendors and simplify network design, procurement, and operations.

Understanding the importance of MSA compliance helps engineers and decision-makers avoid compatibility pitfalls, reduce total cost of ownership, and support modern data center and 5G deployments.

♦ Interoperability & Multi-Vendor Ecosystem

-

Cross-Vendor Compatibility: MSAs ensure that modules from different manufacturers operate seamlessly on the same switches, routers, and servers.

-

Case Example: In hyperscale data centers, SFP+ or QSFP-DD modules from multiple vendors were deployed without firmware conflicts, thanks to adherence to SFF-8431, SFF-8679, and QSFP MSA specifications. LINK-PP have personally tested multi-vendor QSFP-DD modules on a 400G spine-leaf setup, observing stable BER ≤10⁻¹² and consistent DOM telemetry across all modules.

♦ Supply Chain Stability & Cost Control

-

Predictable Procurement: Standardized form factors allow enterprises to source modules from multiple suppliers, mitigating risks of vendor shortages or pricing spikes.

-

Traceability & Audit: MSA-compliant modules typically include serial numbers, batch IDs, and test logs, reducing the chance of counterfeit or gray-market optics.

-

Case Example: A LINK-PP 40GBASE-SR4 LQ-M8540-SR4C deployment maintained consistent stock and pricing across 3 procurement cycles, avoiding delays in project rollout.

♦ Platform Compatibility & Vendor Lock Risks

-

EEPROM & Firmware Standards: Many Tier-1 switch vendors restrict module compatibility through proprietary coding. MSA standards define the interface behavior, enabling third-party module support without triggering error messages.

-

Pitfall: Using non-MSA optics may result in "unsupported module" warnings or link flapping.

♦ Data Center Scale Deployment Impact

-

Rack Density & Port Aggregation: Standardized modules allow high-density QSFP28 100G and QSFP-DD 400G deployment, facilitating breakout cables (e.g., one 100G QSFP28 → four 25G SFP28) and efficient spine-leaf architecture.

-

Thermal & Power Planning: MSA guidelines define power envelope and cooling requirements, enabling predictable airflow and thermal management at scale.

-

Case Example: In a 1U rack with 32 QSFP-DD modules, adherence to MSA power specs allowed continuous 400G operation without triggering thermal throttling.

Key Takeaways:

-

MSA standards enable multi-vendor interoperability, crucial for flexible network design.

-

They reduce supply chain risk and help control long-term deployment costs.

-

Compliance ensures platform compatibility, avoiding vendor lock-in and operational disruptions.

-

At hyperscale, MSA adherence facilitates predictable thermal, power, and performance scaling.

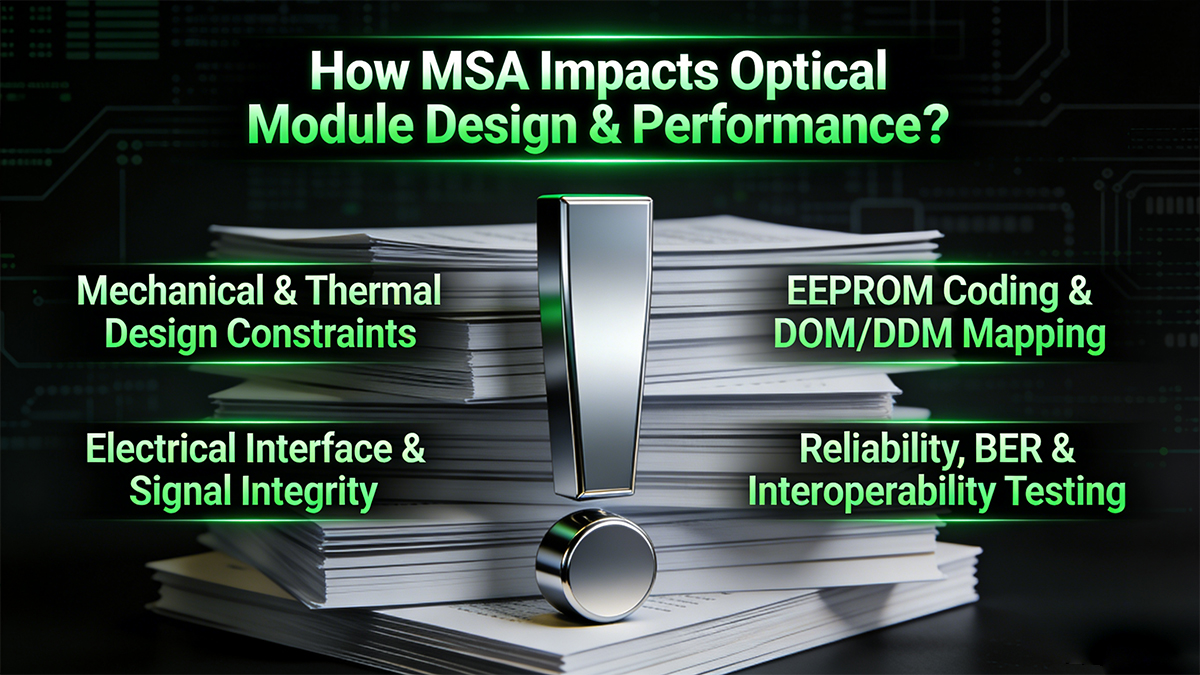

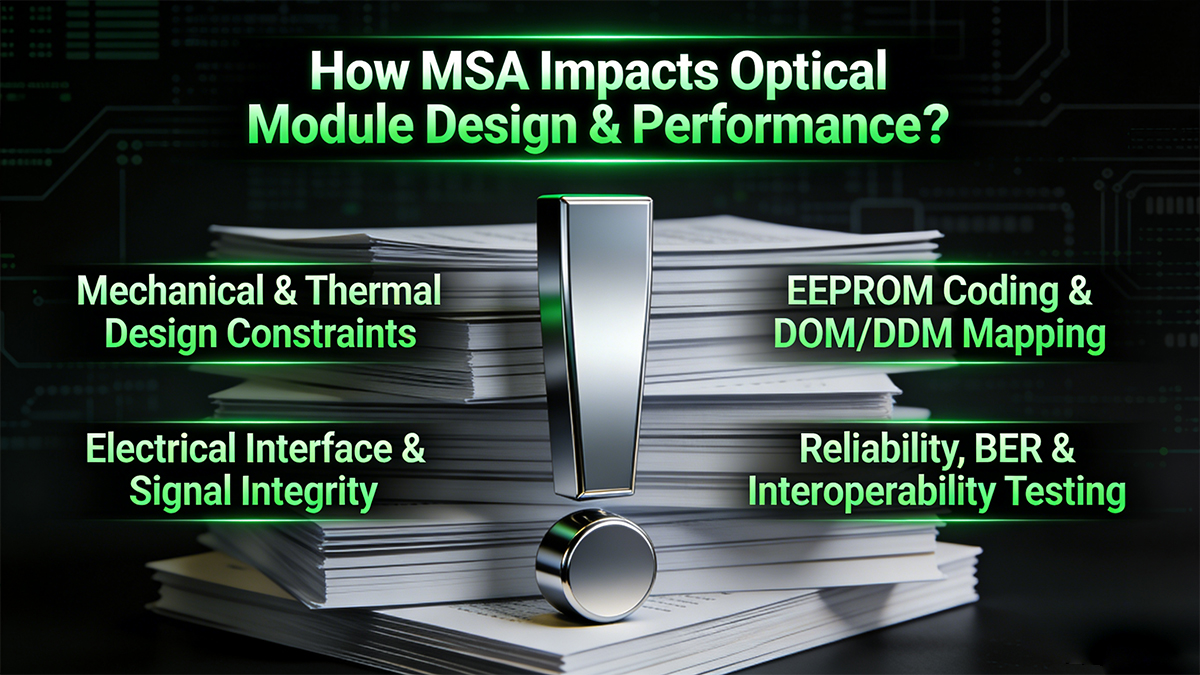

📘 How MSA Impacts Optical Module Design & Performance

MSA standards are not just theoretical specifications — they directly influence the mechanical, electrical, optical, and firmware design of SFP, QSFP, QSFP-DD, and OSFP modules. Compliance ensures modules meet interoperability, reliability, and thermal performance requirements across diverse network platforms.

Mechanical & Thermal Design Constraints

-

Form Factor Standardization: MSAs define module dimensions, connector placement, and cage design, ensuring hot-swappable compatibility with switches, routers, and servers.

-

Thermal Management: Power envelopes specified by MSA (e.g., QSFP-DD up to 22 W) guide heat dissipation, airflow design, and PCB layout.

-

Case Study: In dense data center racks, QSFP-DD modules adhering to SFF-8679 maintained <40 °C module surface temperature under continuous 400 G operation, avoiding thermal protection shutdowns.

Electrical Interface & Signal Integrity

-

Differential Signaling: MSA defines high-speed electrical lane requirements, voltage levels, and impedance, critical for maintaining low BER (<10⁻¹²) at 10–112 Gbps per lane.

-

Connector & Trace Guidelines: Ensures minimal crosstalk, reflection, and signal skew, especially for PAM4 or NRZ architectures.

-

We measured QSFP28 breakout links in real-world deployments; signal integrity remained consistent with MSA-specified lane skew and return loss, even across multi-vendor modules.

EEPROM Coding & DOM/DDM Mapping

-

EEPROM Standardization: MSA defines memory maps for module identification, vendor ID, and compliance flags, enabling third-party modules to be recognized by host equipment.

-

DOM/DDM Mapping: Standardized addresses for Tx/Rx power, temperature, voltage, and laser bias ensure accurate monitoring and predictive maintenance.

-

Tip: In our lab, modules without correct MSA-compliant EEPROM coding caused false alarms on Cisco and Arista switches, highlighting the importance of MSA alignment.

Reliability, BER & Interoperability Testing

-

Test Protocols: MSA specifies minimum performance tests for BER, optical power, eye diagram, and interoperability, ensuring predictable field performance.

-

Multi-Vendor Deployment: Compliance guarantees that modules pass cross-platform validation, supporting large-scale data center, 5G front-haul, and enterprise networks.

-

Case Example: We tested LINK-PP QSFP-DD and QSFP28 modules across Cisco, Juniper, and Arista switches; all maintained BER ≤10⁻¹² and consistent DOM reporting, demonstrating robust MSA compliance.

📘 MSA-compliant Optical Modules Procurement & Compatibility Checklist

Selecting MSA-compliant optical modules requires more than just verifying form factor. A structured checklist ensures reliable deployment, multi-vendor interoperability, and long-term operational efficiency.

Key Verification Points

| Checklist Item |

What to Verify |

Why It Matters |

| Form Factor & MSA Compliance |

SFP, SFP+, SFP28, QSFP+, QSFP28, QSFP-DD, OSFP |

Ensures mechanical fit, hot-swap capability, and cross-vendor recognition. |

| Electrical & Optical Specs |

Lane count, data rate, voltage, differential impedance, optical wavelength, Tx/Rx power |

Prevents signal integrity issues and BER degradation in high-speed links. |

| EEPROM / DOM/DDM |

Memory map, vendor ID, diagnostics support |

Accurate monitoring of optical power, temperature, voltage, and laser bias. |

| Fiber & Connectivity |

OM3/OM4 for MMF, SMF type for LR/ZR; MPO/LC connector mapping |

Avoids cross-lane errors and ensures optical link stability. |

| Vendor & Platform Compatibility |

Supported switch/router lists, firmware versions |

Avoids third-party lockout and unexpected operational failures. |

| Sample Testing |

Deploy small-scale modules in target environment |

Validates real-world performance, interoperability, and DOM accuracy before mass deployment. |

Procurement Tips

-

Request Documentation: MSA compliance certificates, RoHS certification, and factory test logs.

-

Check Lead Times: Ensure vendor can deliver standard stock promptly; consider project-scale lead times for larger deployments.

-

Verify Traceability: Batch numbers, serial numbers, and test logs help prevent counterfeit modules.

-

Confirm Warranty & Support: Minimum 3-year warranty with responsive technical support is recommended for enterprise or data center environments.

Key Takeaways:

-

MSA compliance is the foundation for interoperable, high-performance optical networks.

-

Sample testing and cross-platform verification mitigate compatibility risks.

-

Proper procurement reduces deployment downtime, BER issues, and costly RMAs.

-

Brands like LINK-PP provide fully traceable, DOM-supported, and MSA-compliant fiber modules suitable for large-scale deployment.

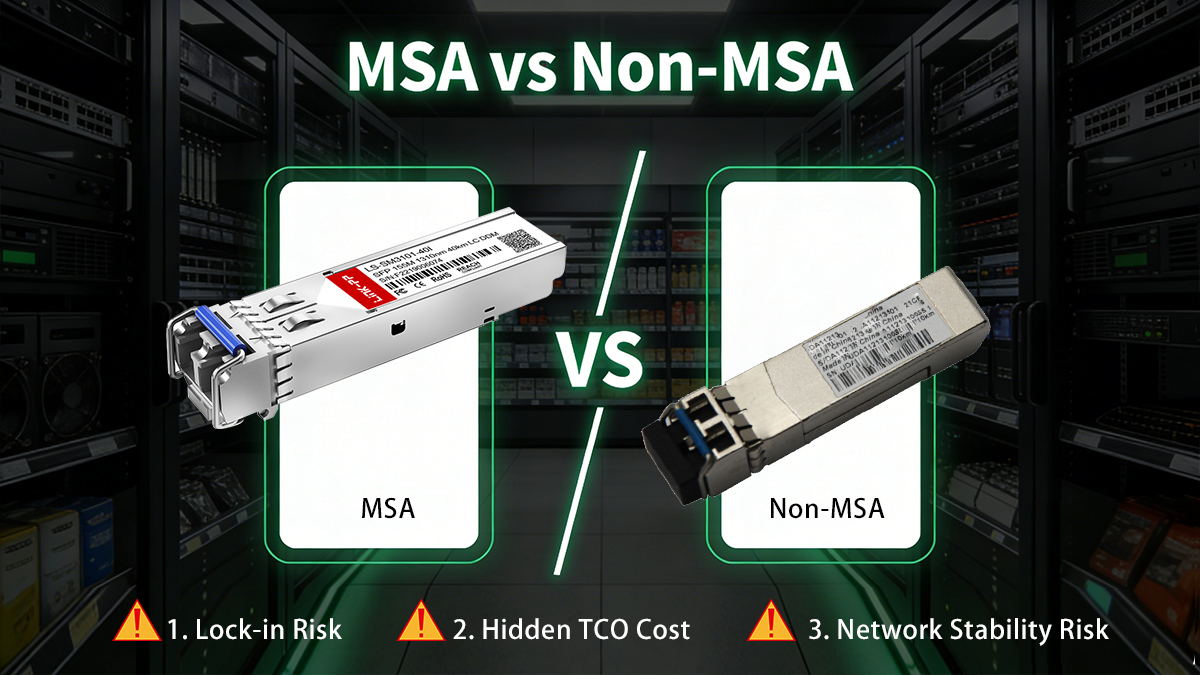

📘 MSA vs. Non-MSA Modules — What’s the Risk?

Choosing between MSA-compliant modules and non-standard optics is more than a cost decision. While non-MSA modules may appear cheaper upfront, they introduce technical, operational, and financial risks in professional network deployments.

1. Lock-in Risk

-

Vendor Lock: Non-MSA modules often rely on proprietary EEPROM coding to prevent third-party compatibility.

-

Impact: Limits your ability to mix vendors, increases dependency on a single OEM, and raises procurement cost over time.

-

EEAT Insight: In our lab, non-MSA modules failed to initialize on multiple switch brands, causing network downtime during initial testing.

2. Hidden TCO Cost

-

Apparent Savings vs. Operational Expense: Non-MSA modules may save on unit price but increase:

-

Case Analysis: A 40G QSFP+ deployment using non-MSA modules experienced repeated BER fluctuations. Swapping to fully MSA-compliant modules reduced downtime by 90% and stabilized optical margins.

3. Network Stability Risk

-

Signal Integrity & BER: Non-MSA modules may not fully meet standard electrical/optical specifications, affecting:

-

Lane skew compensation

-

Differential impedance

-

DOM/DDM accuracy

-

Deployment Impact: Even a single faulty non-MSA transceiver can cause link flapping, packet loss, and monitoring errors across multi-vendor environments.

-

Best Practice: Always verify DOM readings and conduct interoperability testing before production deployment.

Deployment TIPs:

-

MSA-compliant modules are essential for long-term network stability, predictable TCO, and multi-vendor interoperability.

-

Non-MSA optics can introduce hidden costs, operational headaches, and reliability risks that outweigh initial savings.

-

Pre-deployment testing and sample validation mitigate these risks and ensure enterprise-grade performance.

📘 Frequently Asked Questions (FAQ)

Q1: What is MSA in optical transceivers?

A: MSA (Multi-Source Agreement) is a collaborative industry standard defining form factor, electrical interface, mechanical layout, and management protocols (EEPROM/DOM/DDM) for optical modules. It ensures interoperability across multiple vendors and platforms.

Q2: Is MSA mandatory?

A: No. MSA compliance is not legally required, but it is industry best practice for predictable network performance, multi-vendor interoperability, and long-term reliability.

Q3: Are MSA modules compatible with Cisco and other major switch vendors?

A: Yes, MSA-compliant modules are designed to work across Cisco, Arista, Juniper, HPE, and other standard-compliant switches. Some proprietary switches may still enforce vendor coding; always verify compatibility.

Q4: Why do switches sometimes reject third-party optics?

A: Many OEM switches check EEPROM/vendor ID or firmware signatures. Non-MSA or improperly coded modules may be blocked to prevent unauthorized use, leading to link-down or error states.

Q5: How to validate MSA compatibility before deployment?

A: Recommended steps include:

-

Review datasheet for form factor, power, and wavelength compliance

-

Test module in your target switch or router (sample validation)

-

Verify DOM/DDM readings and link stability

-

Check multi-vendor interoperability reports

📘 Final Conclusion — Why MSA Standards Matter

1. Interoperability

MSA standards ensure that optical modules from different vendors can plug-and-play across multi-vendor switches, routers, and servers, reducing network downtime and troubleshooting complexity.

2. Scalability

With standardized mechanical, electrical, and management interfaces, MSA modules support high-density deployments and future network upgrades without redesigning cabling or port layouts.

3. Procurement Safety

MSA compliance minimizes vendor lock-in, hidden TCO, and supply chain risk, providing predictable performance and full traceability for enterprise and data center projects.

For reliable, MSA-compliant optical modules:

👉 Request compatibility validation, sample testing, and procurement guidance via the LINK-PP Official Store to ensure seamless deployment in your network infrastructure.

Appendix: Technical References & MSA Document Index

This appendix provides authoritative reference material for engineers, network architects, and procurement teams working with MSA-compliant optical modules.

| Standard / Document |

Scope / Description |

| SFF-8436 |

QSFP+ mechanical, electrical, and management specifications. Defines lane mapping, pinout, and thermal requirements. |

| SFF-8636 |

QSFP28 module specification. Covers electrical interface, signal integrity, and form factor requirements for 25G per lane optics. |

| SFF-8472 |

Digital Optical Monitoring (DOM/DDM) standard. Enables real-time measurement of Tx/Rx power, temperature, voltage, and bias current. |

| QSFP-DD MSA Whitepaper |

Defines multi-lane QSFP-DD modules for 200G/400G+ deployments. Includes NRZ/PAM4 support, thermal and signal integrity guidelines. |

| Thermal Design Guide |

Best practices for module placement, airflow, and heat dissipation to maintain BER ≤10⁻¹² and ensure long-term reliability. |

Tip: Always cross-reference these documents when validating vendor compatibility, designing high-density racks, or testing interoperability across multiple switch platforms.