As 10-Gigabit Ethernet becomes standard in enterprise networks and data centers, choosing the right physical interface is just as important as selecting the switch or server itself. While fiber-based SFP+ modules and direct attach cables (DAC) dominate many high-speed deployments, 10G Copper SFP modules remain a practical and cost-effective option in specific scenarios.

A 10G Copper SFP allows network devices to deliver 10GbE connectivity over standard twisted-pair copper cabling, typically Cat6a or better. This makes it especially attractive when upgrading existing copper infrastructure, connecting nearby equipment, or simplifying short-range links without introducing fiber handling complexity.

This guide focuses on when you should use a 10G Copper SFP module, rather than simply explaining what it is. You will learn the ideal use cases, technical limitations, and key trade-offs compared with fiber and DAC alternatives, helping you decide whether a 10G Copper SFP is the right choice for your network design.

🔷 What Is a 10G Copper SFP?

A 10G Copper SFP is an SFP+ form-factor transceiver designed to deliver 10-Gigabit Ethernet over copper twisted-pair cabling. It implements the IEEE 802.3an 10GBASE-T standard, enabling 10GbE links using familiar RJ45 connectors instead of optical fiber.

Unlike SFP+ fiber transceiver that convert electrical signals into light, a 10G Copper SFP performs high-speed electrical signaling and advanced digital signal processing (DSP) to transmit data reliably over copper cables. This makes it a practical option for short-reach connections where fiber is unnecessary or existing copper infrastructure is already in place.

10GBASE-T Explained in Simple Terms

10GBASE-T is the Ethernet standard that defines how 10Gbps data is transmitted over copper cables.

In simple terms:

-

It allows 10GbE to run over Cat6a cables up to 100 meters

-

It uses RJ45 connectors, the same interface as 1G Ethernet

-

It relies on complex encoding and error correction to overcome copper noise and crosstalk

Compared to lower-speed copper Ethernet (1G or 2.5G), 10GBASE-T requires higher signal quality and more processing power, which directly affects power consumption and heat generation in 10G Copper SFP modules.

How a 10G Copper SFP Works in Ethernet Networks

In a live network, a 10G Copper SFP functions as an electrical-to-electrical transceiver:

-

A 10GbE electrical signal is generated by the switch or NIC

-

The SFP module’s internal PHY and DSP encode and condition the signal

-

Data is transmitted over twisted-pair copper cable using all four pairs

-

At the receiving end, the signal is decoded and reconstructed into Ethernet frames

Because all signal processing occurs inside the module, the switch sees the 10G Copper SFP as a standard SFP+ interface, while the copper PHY logic is fully contained within the transceiver.

Copper vs Fiber Signal Transmission Basics

Understanding the difference between copper and fiber transmission helps clarify when a 10G Copper SFP+ makes sense.

Copper transmission characteristics:

-

Electrical signals over twisted-pair cable

-

Susceptible to EMI, crosstalk, and attenuation

-

Higher power draw due to DSP and error correction

-

Uses RJ45 connectors and standard Ethernet cabling

Fiber transmission characteristics:

-

Optical signals over glass fiber

-

Immune to electromagnetic interference

-

Lower latency and power consumption

-

Requires optical handling, cleaning, and polarity management

In short, 10G Copper SFPs trade efficiency for convenience, offering Ethernet compatibility and deployment simplicity at the cost of higher power and shorter practical reach compared to fiber SFP+ modules.

🔷 Key Advantages and Limitations of 10G Copper SFPs

Before choosing a 10Gb Copper SFP module, it is important to understand what it does well—and where it falls short. These transceivers are not designed to replace fiber in all 10GbE deployments, but they can be highly effective when used in the right scenarios.

Advantages of 10G Copper SFP

1. Uses existing copper infrastructure

One of the biggest advantages is compatibility with standard Cat6a (or better) Twisted-Pair Copper Cable. In environments where copper Ethernet is already installed, upgrading to 10GbE may not require new fiber runs or additional optical components.

2. Familiar RJ45 interface

10G Copper SFPs terminate with RJ45 connectors, making them easy to deploy for teams accustomed to traditional Ethernet cabling. This reduces installation complexity and minimizes the risk of fiber handling errors.

3. Flexible auto-negotiation support

Most Copper 10G SFP modules support backward speed compatibility (1G / 2.5G / 5G, depending on the module and switch), which can be useful during phased network upgrades.

4. Ideal for short-range links

For short-distance connections—such as switch-to-server or switch-to-switch links within the same rack or row—10G Copper SFPs offer a simple and practical solution without introducing fiber management overhead.

Limitations of 10G Copper SFP

1. Higher power consumption

Compared with fiber SFP+ or DAC cables, 10G Copper SFPs consume significantly more power due to onboard PHY and DSP processing. This can impact:

2. Increased heat generation

Higher power draw results in more heat output, which may trigger port-level power restrictions or thermal alarms on some switches, especially in densely populated environments.

3. Practical distance constraints

Although the 10GBASE-T standard supports up to 100 meters on Cat6a, real-world deployments may experience reduced reliability at longer distances, particularly with suboptimal cabling or EMI-heavy environments.

4. Higher latency compared to fiber and DAC

The signal processing required for copper transmission introduces slightly higher latency than fiber-based SFP+ modules or direct attach copper (DAC), which can matter in latency-sensitive applications.

In summary, 10G SFP+ Copper Modules prioritize deployment convenience and compatibility, while fiber and DAC options excel in efficiency, scalability, and performance. Understanding these trade-offs is critical when deciding whether a 10G Copper SFP is the right fit for your network.

🔷 When Should You Use a 10G Copper SFP? (Key Use Cases)

A 10G Copper SFP is best used in short-range, cost-conscious, and copper-friendly environments. It is not designed to replace fiber in high-density or long-distance networks, but it can be the most practical choice in specific deployment scenarios.

Below are the most common and recommended use cases where a 10G Copper SFP module makes technical and operational sense.

Short-Distance 10G Ethernet Links (Up to 30m)

10Gbe Copper SFP modules perform best in short-distance connections, typically within the same rack, between adjacent racks, or across nearby cabinets.

In these scenarios:

-

Cable lengths are well within stable operating ranges

-

Latency and signal loss are minimal

-

Thermal impact is easier to manage

For short links, copper SFPs provide reliable 10GbE connectivity without the need for optical fiber, making them a convenient alternative to fiber or DAC cables.

Upgrading to 10G Using Existing Copper Cabling

When a network already uses Cat6 or Cat6a twisted-pair cabling, a 10G Copper SFP allows a straightforward upgrade to 10GbE without replacing the physical cabling infrastructure.

Key advantages include:

This makes 10G Copper SFP especially suitable for incremental network upgrades in enterprise offices and legacy data center environments.

Cost-Sensitive Network Deployments

In scenarios where budget constraints are a primary concern, 10G Copper SFP modules can help control upfront deployment costs, particularly when fiber infrastructure is not already in place.

Compared with fiber-based solutions:

-

No optical transceivers are required

-

No fiber patch cords or cleaning tools are needed

-

Installation and troubleshooting are simpler

While power consumption may be higher, the overall cost can still be lower for small-scale or short-distance deployments.

IT Environments Favoring Simple Installation

For IT teams that prioritize ease of installation and maintenance, copper-based solutions offer a familiar and straightforward workflow.

Benefits include:

This simplicity reduces the risk of installation errors and makes 10G Copper SFPs attractive for field deployments, branch offices, and fast turn-up environments.

A 10G Copper SFP is the right choice when distance is short, copper is already available, and simplicity matters more than power efficiency. Understanding these use cases helps ensure the module is applied where it delivers maximum value—without compromising network reliability.

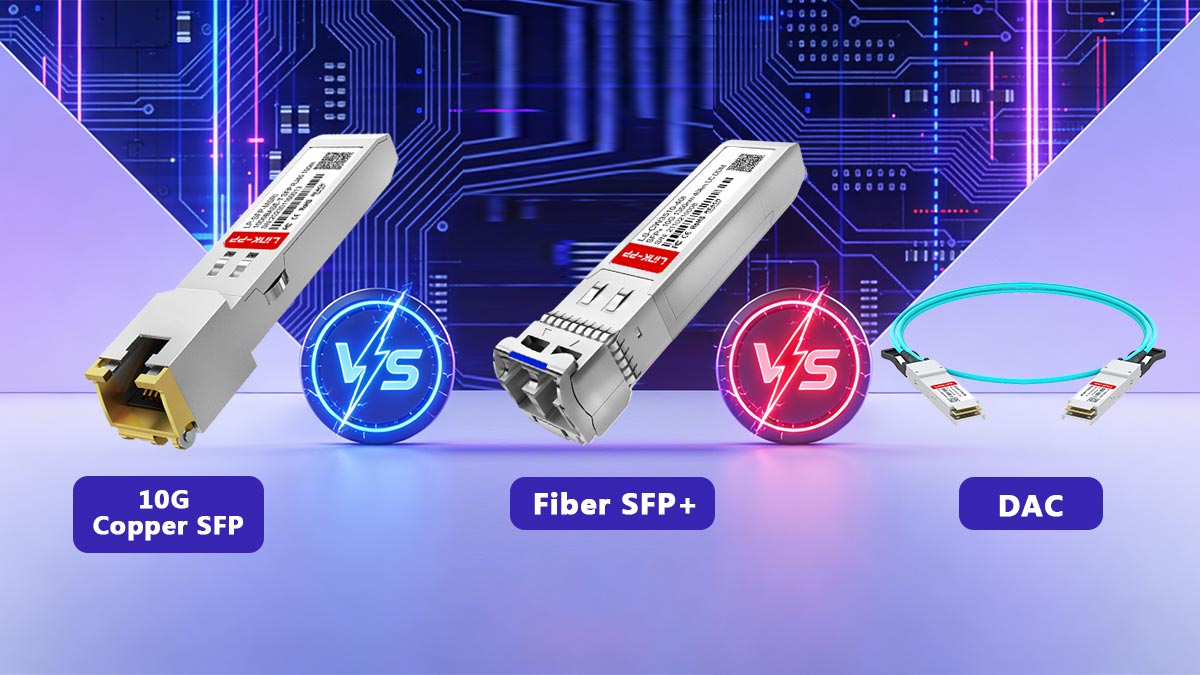

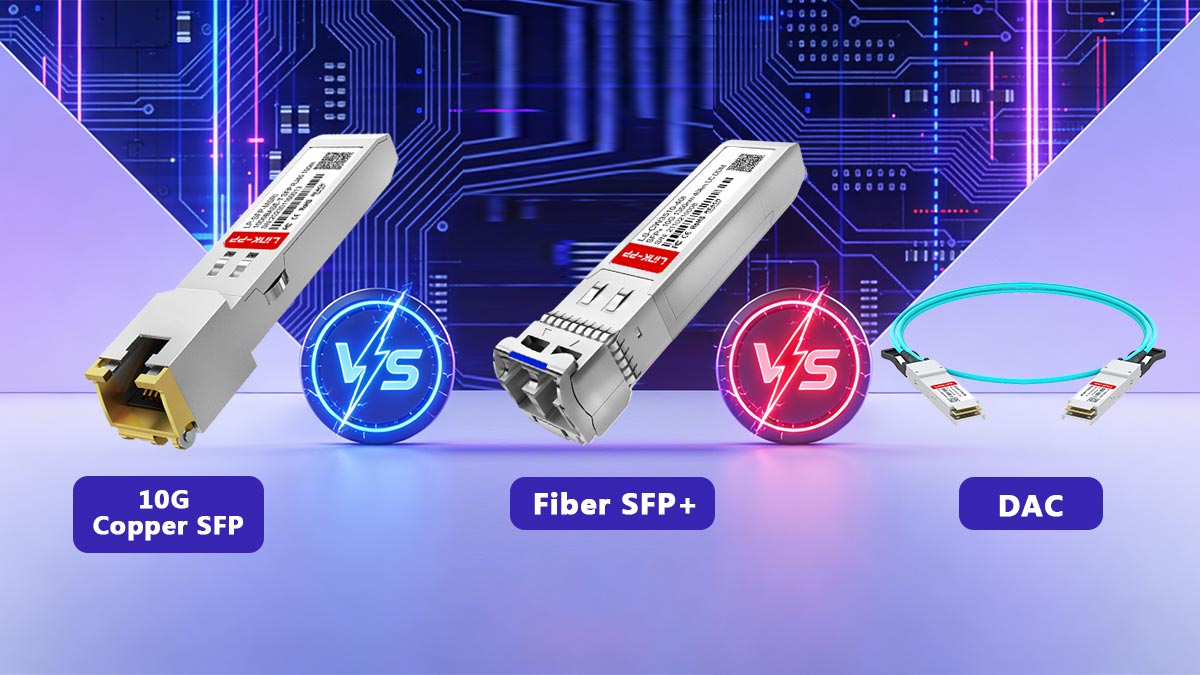

🔷 10G Copper SFP vs. Fiber SFP+ vs. DAC

Choosing the right 10GbE interface depends on distance, power efficiency, cabling infrastructure, and operational flexibility. While 10G Copper SFPs, fiber-based SFP+ modules, and DAC cables all support 10GbE, their real-world performance and use cases differ significantly.

This section provides a practical comparison to help you select the most suitable option.

▶ 10G Copper SFP vs Fiber SFP+: Which One Should You Choose?

Distance and Latency Comparison

Fiber SFP+ modules—such as 10G SFP+ SR or other 10G fiber modules—are designed for low-latency, long-distance transmission.

-

Fiber SFP+ SR: up to 300 m on multimode fiber

-

Fiber SFP+ LR: up to 10 km on single-mode fiber

-

10Gb SFP Copper: typically optimized for short links (often ≤30 m in practice)

Copper-based transmission requires additional signal processing, resulting in slightly higher latency than fiber solutions.

Power Consumption Considerations

Power efficiency is a major differentiator:

-

10G Copper SFP: highest power consumption due to PHY and DSP processing

-

Fiber SFP+ modules: significantly lower power draw

-

DAC cables: lowest power consumption

In high-density switches, fiber SFP+ modules are often preferred to avoid thermal and port power limitations.

Cable Type and Infrastructure Requirements

Copper solutions favor familiarity and speed of deployment, while fiber offers superior scalability.

Cost and Maintenance Differences

From a cost perspective:

-

10G Copper SFPs may reduce initial deployment cost in copper-heavy environments

-

Fiber SFP+ modules involve additional costs for fiber patch cords and optical accessories

-

Fiber links require stricter maintenance (cleaning, inspection, handling discipline)

Over time, however, power efficiency and thermal savings can make fiber more economical in large-scale deployments.

▶ 10G Copper SFP vs 10G DAC Cable

Flexibility and Reach

DAC cables are fixed-length assemblies, typically limited to short distances (1–7 m, sometimes up to 10 m).

In contrast, 10G Copper SFPs:

-

Support variable cable lengths

-

Allow reuse of existing structured cabling

-

Provide more flexibility for layout changes

Use Cases Where Copper SFP Is Preferred

A 10G Copper SFP is often the better choice when:

-

Link distance exceeds typical DAC lengths

-

Patch panel or structured cabling is required

-

RJ45 connectivity is preferred for operational reasons

-

Flexibility outweighs minimal latency differences

Limitations of DAC in Certain Deployments

While DACs are efficient, they may be unsuitable when:

-

Cabling paths require bends or patch panels

-

Cable replacement or re-routing is frequent

-

Mixed-speed or transitional environments are involved

In such cases, copper SFP modules offer greater deployment adaptability.

▶ Comparison Summary

| Feature |

10G Copper SFP |

Fiber SFP+ |

DAC Cable |

| Distance |

Short (best ≤30 m) |

Medium to long |

Very short |

| Latency |

Higher |

Low |

Very low |

| Power Consumption |

High |

Low |

Very low |

| Cabling |

Cat6 / Cat6a |

MMF / SMF |

Fixed copper |

| Flexibility |

High |

Medium |

Low |

Key Takeaway

-

Choose 10G Copper SFP for short-range, copper-based, flexible deployments

-

Choose fiber SFP+ modules for efficiency, scalability, and longer distances

-

Choose DAC cables for ultra-short, low-power, high-density connections

🔷 When NOT to Use a 10G Copper SFP?

While 10G Copper SFP modules are practical in specific scenarios, they are not a universal solution for all 10GbE deployments. Understanding when not to use them is just as important as knowing their advantages.

The following situations highlight where alternative options—such as fiber SFP+ modules or DAC cables—are technically more appropriate.

Long-Distance Network Connections

10G Copper SFP modules are fundamentally limited by twisted-pair cabling constraints.

Even though the 10GBASE-T standard supports up to 100 meters on Cat6a, in real-world environments:

-

Signal stability may degrade over longer runs

-

EMI and cabling quality have a greater impact

-

Troubleshooting becomes more complex

For distances beyond short links, fiber-based 10G SFP+ modules (SR or LR) provide far more consistent performance and reliability.

High-Density or Power-Constrained Data Centers

10G Copper SFPs consume significantly more power per port than fiber SFP+ modules or DAC cables.

In high-density switches, this can lead to:

In such environments, operators typically prefer low-power fiber optics or DACs to maintain thermal stability and maximize port utilization.

Latency-Sensitive Applications

Copper-based 10G transmission requires additional signal processing, introducing slightly higher latency compared to fiber or DAC connections.

While the difference is negligible for many enterprise workloads, it can matter in:

For these applications, fiber SFP+ modules or DAC cables are the preferred choice.

Harsh EMI or Industrial Environments (Without Shielding)

Copper cabling is inherently more susceptible to electromagnetic interference (EMI) than optical fiber.

In environments with:

Unshielded copper links may experience instability. In these cases, fiber optics offer electrical isolation and superior noise immunity.

Professional Recommendation

A SFP 10Gb Copper should be avoided when distance, power efficiency, or signal integrity is critical. Selecting the correct medium for each use case ensures long-term network reliability and reduces operational risk.

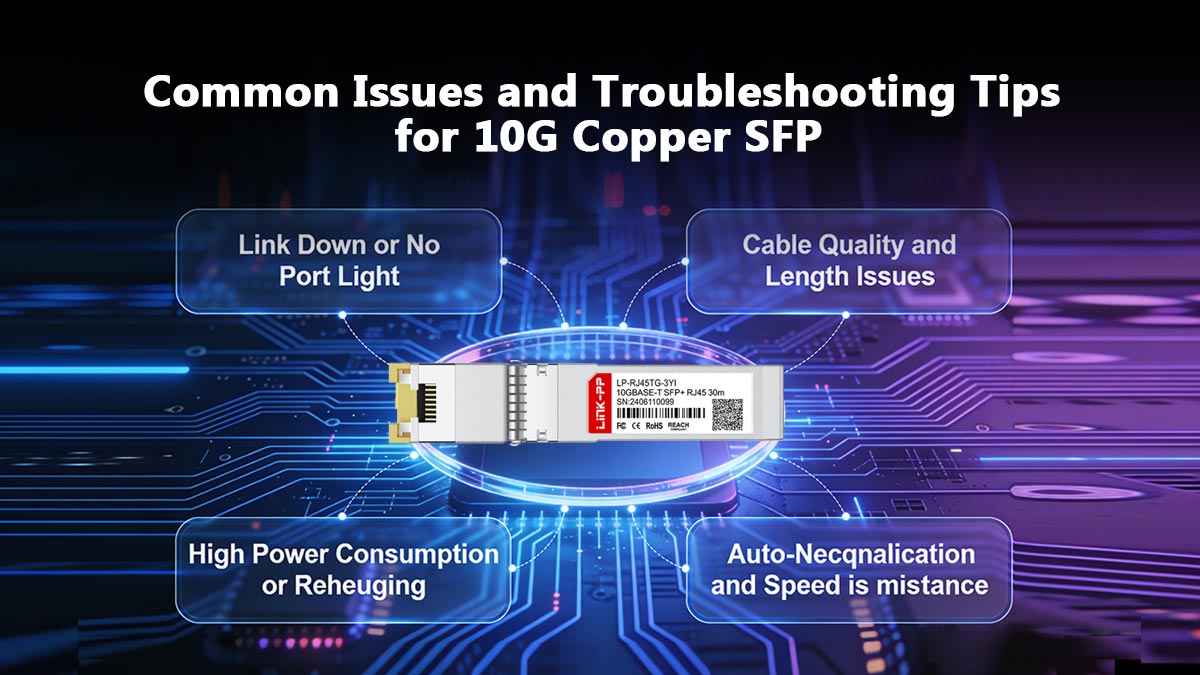

🔷 Common Issues and Troubleshooting Tips for 10G Copper SFP

Although 10G Copper SFP modules are designed for plug-and-play deployment, issues can still occur due to cabling quality, power limitations, or compatibility constraints. Understanding the most common problems helps reduce downtime and speeds up troubleshooting.

Link Down or No Port Light

If the link does not come up after installation, check the following:

-

Ensure the SFP module is fully seated in the SFP+ port

-

Confirm the switch port is 10G-capable and not limited to 1G SFP only

-

Verify that the connected device also supports 10GBASE-T

-

Check that the port is enabled and not administratively shut down

Reseating the module often resolves initial contact issues.

Cable Quality and Length Issues

Copper cabling has a direct impact on link stability:

-

Use Cat6a cabling for optimal performance

-

Keep cable length within recommended ranges, especially in EMI-heavy environments

-

Avoid old, damaged, or poorly terminated cables

Even when Cat6 is supported, marginal cable quality can cause intermittent link drops or auto-negotiation failures.

High Power Consumption or Overheating

10G Copper SFPs consume more power than fiber SFP+ modules.

If you encounter thermal warnings or unstable links:

-

Reduce the number of copper SFPs in adjacent ports

-

Improve airflow around the switch

-

Check whether the switch enforces per-port power limits

In high-density scenarios, consider fiber or DAC alternatives.

Auto-Negotiation and Speed Mismatch

Some issues arise from speed negotiation differences:

-

Confirm both ends support 10GbE

-

Avoid forcing speeds unless required by the platform

-

Verify backward compatibility settings (1G / 2.5G / 5G)

Manual configuration mismatches can prevent the link from establishing.

Switch Compatibility and Firmware Limitations

Not all switches support SFP+RJ45 Module equally.

Best practices include:

-

Confirm module compatibility with the switch vendor

-

Check firmware or OS release notes

-

Update switch software if necessary

Using MSA-compliant modules improves interoperability but does not guarantee universal support.

When to Replace or Reevaluate the Deployment

If issues persist after basic troubleshooting:

-

Test with a known-good cable

-

Try a different SFP+ port

-

Replace the module if overheating or instability continues

In some environments, fiber SFP+ modules or DAC cables may be a better long-term solution.

Key Takeaway

Most 10G Copper SFP issues are deployment-related rather than hardware defects. Careful attention to cabling quality, power limits, and compatibility resolves the majority of problems.

🔷 Typical Applications of 10G Copper SFP

10G Copper SFP modules are commonly used in environments where short-distance 10GbE connectivity, existing copper cabling, and deployment simplicity are prioritized. While not suited for every scenario, they serve a clear role across several practical network applications.

Enterprise Network Upgrades

In enterprise environments, upgrading access or aggregation layers from 1G to 10G often involves existing Cat6 or Cat6a cabling.

10G Copper SFPs enable:

-

Smooth migration to 10GbE without replacing copper infrastructure

-

Reduced disruption during phased upgrades

-

Compatibility with mixed-speed environments

This makes them well suited for office buildings, campus networks, and enterprise core-to-access links.

Data Center Edge Connectivity

At the edge of the data center, where distances are short and port density is moderate, 10G Copper SFPs can provide flexible connectivity between:

They are particularly useful when structured copper cabling or patch panels are already deployed.

Server-to-Switch Copper Links

For server connections requiring 10GbE over RJ45, a 10G RJ45 SFP offers a straightforward alternative to fiber.

Typical use cases include:

-

Servers equipped with 10GBASE-T NICs

-

Short server-to-switch links within the same rack or row

-

Environments favoring copper for maintenance simplicity

These deployments benefit from familiar cabling practices and reduced fiber handling requirements.

Lab, Test, and Temporary Network Setups

10G Copper SFP modules are widely used in labs, test environments, and temporary network setups due to their flexibility and ease of reuse.

Advantages include:

For proof-of-concept testing or short-term deployments, copper SFPs provide a practical and low-friction solution.

Practical Insight

Across these applications, the value of a 10G Copper SFP lies in convenience, compatibility, and short-range practicality—not in maximum efficiency or long-distance performance.

🔷 Choosing the Right 10G Copper SFP

Selecting a 10G Copper SFP module is not just about matching speed. Compatibility, cabling conditions, thermal limits, and long-term availability all play a critical role in ensuring stable 10GbE operation.

The following criteria will help you choose the right module for your network.

MSA Compliance and Switch Compatibility

Always start with MSA (Multi-Source Agreement) compliance.

An MSA-compliant 10G Copper SFP is more likely to work across platforms from vendors such as Cisco, Juniper, HPE, and white-box switches. However, MSA compliance alone does not guarantee universal support.

Best practices include:

-

Checking the switch vendor’s compatibility documentation

-

Verifying supported transceiver power limits per port

-

Testing with the target switch model when possible

For environments using mixed vendors or third-party optics, compatibility-tested modules reduce deployment risk.

Supported Cable Types (Cat6 vs Cat6a)

Cable quality directly affects performance and stability.

When selecting a module, confirm the supported cable specifications and ensure your infrastructure meets those requirements.

Operating Temperature and Reliability

10G SFP+ RJ45 modules generate more heat than fiber SFP+ modules.

Consider:

-

Operating temperature range (commercial vs extended temperature)

-

Airflow direction and switch cooling design

-

Port density and adjacent module heat buildup

In warmer environments or edge deployments, thermal headroom is especially important for long-term reliability.

Vendor Support and Supply Stability

For production networks, consistency matters.

Choosing a supplier with:

helps avoid unexpected compatibility changes or replacement challenges during future expansions.

Practical Recommendation

A well-chosen 10G Copper SFP should be fully compatible with your switch, matched to your cabling quality, and suitable for your thermal environment. Avoid selecting based on price alone—deployment stability and operational efficiency matter more over time.

If you are evaluating MSA-compliant, compatibility-tested 10G Copper SFP modules, you can explore LINK-PP’s 10G Copper SFP options to compare specifications, supported platforms, and deployment scenarios.

🔷 FAQs About 10G SFP+ Copper Transceivers

Q1: How far can a 10G Copper SFP transmit?

A 10G Copper SFP typically supports short-distance 10GbE links, with stable performance most commonly achieved up to 30 meters in real-world deployments. While the 10GBASE-T standard allows up to 100 meters on Cat6a, actual distance depends on cable quality, EMI, and switch power limits.

Q2: Does a 10G SFP+ Copper consume more power than fiber?

Yes. A 10G Copper SFP consumes significantly more power than fiber SFP+ modules due to onboard signal processing. This higher power draw also results in increased heat output, which should be considered in high-density or thermally constrained switches.

Q3: Can I use a 10G SFP+ RJ45 in any SFP+ port?

Not always. Although 10G Copper SFPs are physically compatible with SFP+ ports, switch firmware and per-port power limits determine actual support. Always verify compatibility with the switch vendor or use modules tested for the specific platform.

Q4: Is 10G Copper SFP suitable for data centers?

10G Copper SFPs can be used in data center edge or low-density areas, especially where copper cabling is already present. However, for high-density, power-sensitive, or long-distance data center deployments, fiber SFP+ modules or DAC cables are generally preferred.

Q5: What cable is recommended for 10G Copper SFP?

Cat6a twisted-pair cabling is strongly recommended for reliable 10GbE performance. While Cat6 may work for very short distances, Cat6a offers better noise immunity, stability, and compliance with 10GBASE-T requirements.

Q6: Can you do 10GbE over copper?

Yes, 10GbE can run over copper cabling using the 10GBASE-T standard. A 10G Copper SFP enables 10GbE transmission over Cat6 or Cat6a twisted-pair cables, typically for short-distance links. For best stability and compliance, Cat6a cabling is recommended.

Q7: What is a 10G SFP used for?

A 10G SFP (or SFP+) module is used to provide 10-Gigabit Ethernet connectivity in switches, routers, and servers. Depending on the module type, it can support fiber (SR/LR), direct attach copper (DAC), or 10GBASE-T copper Ethernet, enabling flexible network design based on distance and infrastructure.

Q8: Is SFP+ fiber or copper?

SFP+ is a form factor, not a transmission medium.

It can support fiber (SR/LR), copper (10GBASE-T), or DAC, depending on the module type.

An SFP+ port can support:

-

Fiber SFP+ modules (e.g., 10G SFP+ SR or LR)

-

DAC cables (direct attach copper)

-

10G Copper SFP modules (10GBASE-T, RJ45)

The actual medium—fiber or copper—depends on the installed module, not the port itself.

🔷 Conclusion: Choosing 10G Copper SFP with Confidence

Summary

10G Copper SFP modules play a clear and practical role in modern 10GbE networks. They are not designed to replace fiber optics or DAC cables in every scenario, but they excel in short-distance, copper-based, and deployment-friendly environments.

Throughout this guide, we covered:

-

What a 10G Copper SFP is and how it works

-

When it makes sense to use copper instead of fiber or DAC

-

Key advantages and limitations to consider before deployment

-

Typical applications in enterprise, data center edge, and lab environments

-

How to choose the right module based on compatibility, cabling, and thermal requirements

The key takeaway is simple: 10G SFP+ Copper Modules are most effective when existing copper infrastructure, flexibility, and ease of installation matter more than power efficiency or long-distance reach.

When 10G Copper SFP Is the Right Choice

A 10G Copper SFP is a strong option if your deployment involves:

-

Short 10GbE links within racks or adjacent cabinets

-

Existing Cat6 or Cat6a cabling you want to reuse

-

RJ45-based server or switch connections

-

Cost-conscious or temporary network setups

In these cases, a properly selected copper SFP can deliver reliable performance without unnecessary complexity.

Explore LINK-PP 10G Copper SFP Modules

If you are evaluating MSA-compliant, compatibility-tested 10G Copper SFP modules for enterprise or data center use, LINK-PP offers a range of options designed for stable performance across major switch platforms.

You can explore 10G Copper SFP solutions in LINK-PP Official Store to review specifications, supported environments, and deployment guidance, and select the module that best fits your network requirements.

Final Note

Choosing the right transceiver is not just about speed—it’s about fit, reliability, and long-term operability. Understanding when to use (and when to avoid) 10G Copper SFP modules helps ensure a balanced, future-ready network design.