As 10-Gigabit Ethernet becomes the standard for modern enterprise and data center networks, many IT buyers are looking for cost-effective ways to upgrade without replacing existing copper cabling. 10G SFP copper modules offer a practical solution by delivering 10GbE performance over standard Cat6a or Cat7 cables, combining high speed with simple deployment. However, not all 10G SFP copper transceivers are created equal—differences in compatibility, power consumption, distance support, and vendor quality can directly impact network stability and long-term costs. This guide is designed to help buyers clearly understand what to look for when purchasing 10G SFP copper modules, so you can make a confident, well-informed decision.

✅ What Is 10G SFP Copper?

10G SFP Copper, also known as a 10GBASE-T SFP+ copper transceiver, is a hot-swappable SFP+ module designed to deliver 10Gbps Ethernet over twisted-pair copper cabling. Instead of using optical fiber, it enables 10-Gigabit connections through standard RJ45 Ethernet cables, making it a popular choice for short-reach 10GbE deployments where copper infrastructure already exists.

From a functional perspective, a 10G SFP copper module converts electrical signals from an SFP+ port into 10GBASE-T Ethernet signals, allowing network switches, servers, and NICs with SFP+ slots to connect directly to copper-based networks without additional media converters.

How 10G SFP Copper Works Over Cat6a / Cat7 Cabling

10G SFP copper modules are built to comply with the IEEE 802.3an (10GBASE-T) standard. When inserted into an SFP+ port, the module negotiates a 10Gbps link and transmits data over Cat6a or Cat7 copper cables using advanced signal processing techniques such as:

-

PAM-16 modulation for higher data density

-

Forward error correction (FEC) to maintain signal integrity

-

Auto-negotiation for speed and duplex compatibility

In real-world deployments, most 10G SFP copper modules support:

This makes them well-suited for rack-to-rack, switch-to-server, and short-distance aggregation links in enterprise and data center environments.

Key Differences Between 10G SFP Copper and Fiber-Based SFP+ Modules

While both options use the same SFP+ form factor, 10G SFP copper and fiber-based SFP+ modules serve very different purposes:

-

Transmission medium:

10G SFP copper uses RJ45 copper cables, while fiber SFP+ modules rely on multimode or single-mode optical fiber.

-

Distance:

Copper modules are optimized for short distances (typically up to 100m), whereas fiber SFP+ optics can reach hundreds of meters to several kilometers.

-

Power consumption:

10G SFP copper generally consumes more power than fiber SFP+ modules due to complex signal processing, which can impact switch thermal design.

-

Deployment cost:

Copper solutions often reduce upfront costs by reusing existing Ethernet cabling, while fiber offers better scalability and lower latency for long-term growth.

Understanding these differences is critical when deciding whether 10G SFP copper is the right choice for your specific network environment and upgrade strategy.

✅ Why Choose 10G SFP Copper for Your Network?

For many enterprise and data center buyers, the decision to use 10G SFP copper is driven by practical deployment and budget considerations rather than raw performance alone. When applied in the right scenarios, 10G SFP copper modules can deliver reliable 10GbE connectivity while significantly reducing complexity and total cost of ownership.

Cost Advantages Compared to Fiber Optics

One of the strongest reasons to choose 10G SFP copper is cost efficiency, especially in environments where copper cabling is already deployed. Unlike fiber-based SFP+ solutions, copper transceivers eliminate the need for:

-

New multimode or single-mode fiber runs

-

Fiber patch panels and termination hardware

-

Specialized optical testing and cleaning tools

In many cases, organizations can reuse existing Cat6a or Cat7 Ethernet cabling, which lowers both material and labor costs. For short-distance links, the overall expense of a 10G SFP copper deployment is often lower than installing new fiber, making it an attractive option for budget-conscious network upgrades.

Plug-and-Play Installation with Existing Copper Infrastructure

10G SFP copper modules are designed for simple, plug-and-play deployment. Once inserted into a compatible SFP+ port, the module automatically negotiates speed and duplex settings with the connected device over standard RJ45 Ethernet cables.

Key operational benefits include:

-

No need to retrain staff on fiber handling procedures

-

Familiar RJ45 connections for IT teams

-

Faster installation and troubleshooting compared to optical links

This ease of use makes 10G SFP copper especially appealing in enterprise environments where minimizing downtime and operational complexity is a priority.

Ideal Scenarios for Short-Range 10G Ethernet Connections

While not intended for long-distance transmission, 10G SFP copper excels in short-range 10GbE applications, such as:

-

Switch-to-server connections within the same rack or adjacent racks

-

Top-of-Rack (ToR) deployments in data centers

-

Enterprise access and aggregation layers with limited link distances

-

Test labs and temporary setups where flexibility and rapid deployment are required

In these scenarios, 10G SFP copper provides a balanced combination of performance, affordability, and deployment speed—making it a practical choice when fiber’s long reach is unnecessary.

✅ Key Specifications to Check Before Buying 10G SFP Copper

Before purchasing a 10G SFP copper module, it is critical to review several technical specifications that directly affect performance, compatibility, and long-term reliability. Unlike fiber SFP+ optics, copper-based 10G modules place higher demands on cabling quality and switch hardware, making specification checks especially important for stable operation.

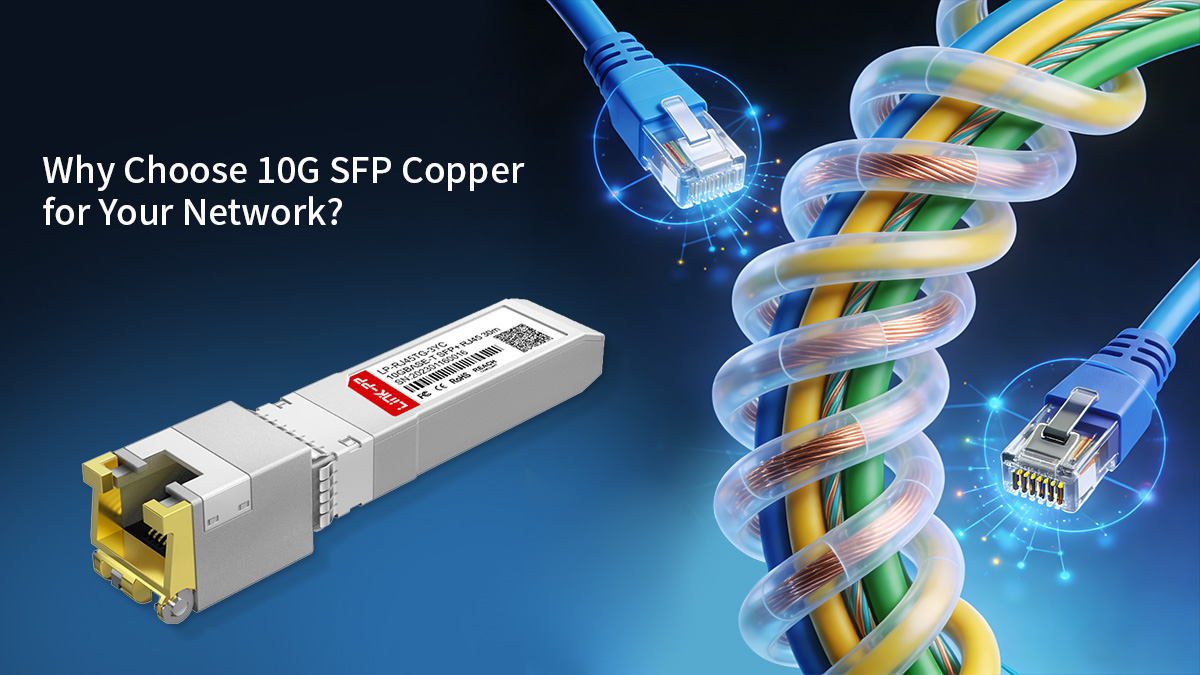

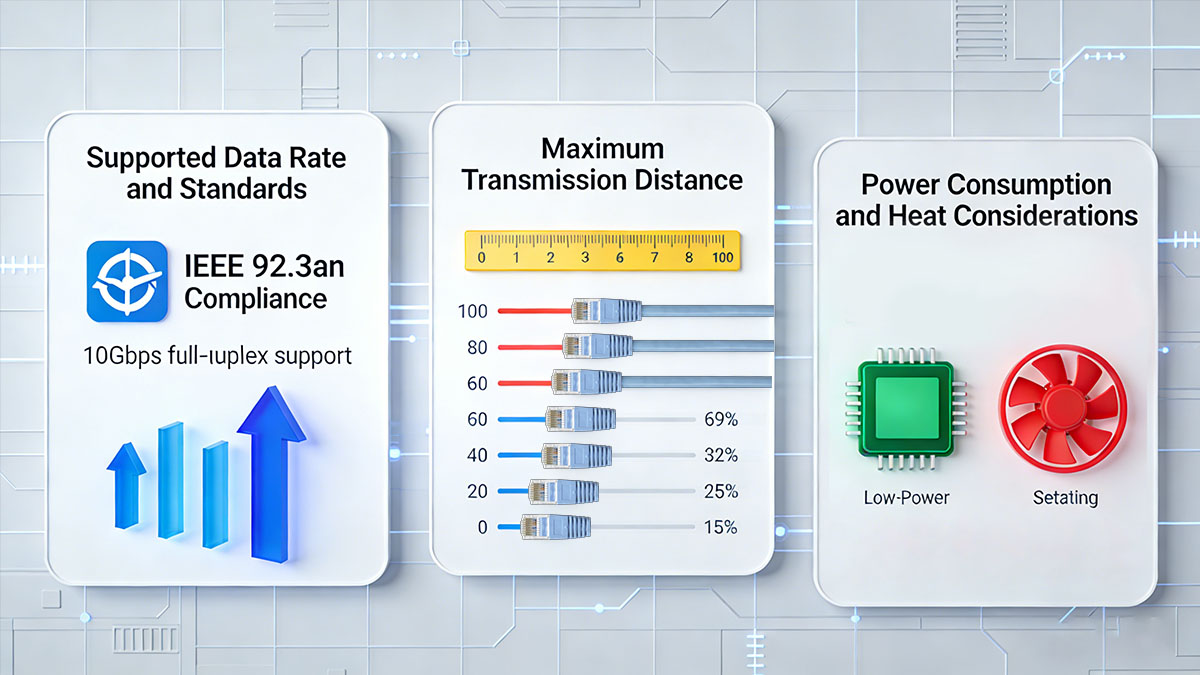

Supported Data Rate and Standards

A reliable 10G SFP copper module should fully comply with the IEEE 802.3an (10GBASE-T) standard. This ensures consistent performance and interoperability across different network devices.

Key points to verify include:

-

10Gbps full-duplex support, enabling simultaneous data transmission and reception

-

Backward compatibility with lower Ethernet speeds (in some models) via auto-negotiation

-

MSA-compliant electrical and mechanical design for SFP+ ports

Standards compliance is essential when deploying third-party transceivers, as non-compliant modules may cause link instability or fail to be recognized by switches and NICs.

Maximum Transmission Distance

Transmission distance is one of the most practical limitations of 10G SFP copper modules and depends heavily on cable quality.

Typical supported distances include:

-

Up to 30 meters over Cat6 copper cabling

-

Up to 80 meters over high-quality Cat6a

-

Up to 100 meters over Cat6a or Cat7 in optimal conditions

Using lower-grade or poorly terminated cables can significantly reduce achievable distance or prevent the link from reaching full 10Gbps speeds. For this reason, Cat6a is generally recommended for stable and future-proof 10GBASE-T deployments.

Power Consumption and Heat Considerations

Compared to fiber-based SFP+ optics, 10G SFP copper modules consume more power due to the complex signal processing required for 10GBASE-T transmission.

Typical characteristics include:

Before deployment, it is important to confirm that your switch:

-

Supports high-power SFP+ copper modules

-

Has adequate airflow and cooling capacity

-

Does not impose per-port power limitations

Ignoring power and thermal requirements can lead to port shutdowns, reduced module lifespan, or overall network instability.

✅ 10G SFP Copper Compatibility Guide

Compatibility is one of the most common concerns when purchasing 10G SFP copper modules. Unlike passive DAC cables, active 10GBASE-T SFP+ transceivers rely heavily on switch firmware recognition, power support, and standards compliance. Understanding compatibility factors in advance helps avoid costly deployment issues and unexpected downtime.

Switch and NIC Compatibility

Most modern switches and network interface cards with SFP+ ports can support 10G SFP copper modules, provided they meet power and firmware requirements. Commonly supported platforms include vendors such as:

-

Cisco

-

Ubiquiti

-

Arista

-

Juniper

-

MikroTik

-

HPE

However, compatibility is not guaranteed by form factor alone. The most important requirement is MSA (Multi-Source Agreement) compliance, which ensures that the module adheres to standardized electrical, mechanical, and signaling specifications.

MSA-compliant 10G SFP copper modules are more likely to:

-

Be recognized correctly by different vendors’ switches

-

Support stable auto-negotiation at 10Gbps

-

Reduce the risk of firmware-related port errors or lockouts

For best results, buyers should always verify the vendor’s compatibility list or confirm that the module has been tested with their specific switch or NIC model.

Third-Party vs OEM 10G SFP Copper Modules

When selecting a 10G SFP copper module, buyers typically choose between OEM-branded optics and third-party alternatives. Each option has distinct trade-offs.

Cost comparison is often the deciding factor. OEM modules are significantly more expensive, while high-quality third-party 10G SFP copper transceivers can offer substantial savings without sacrificing performance.

From a technical standpoint:

-

Reputable third-party modules use vendor-specific firmware coding to ensure proper identification and compatibility

-

Proper auto-negotiation behavior is essential for stable 10GBASE-T links

-

Poorly coded modules may cause link flapping or reduced speeds

Warranty and support also play a critical role. Trusted third-party manufacturers typically provide:

For cost-sensitive deployments, well-tested third-party 10G SFP copper modules can be a reliable and economical alternative to OEM optics when sourced from a reputable supplier.

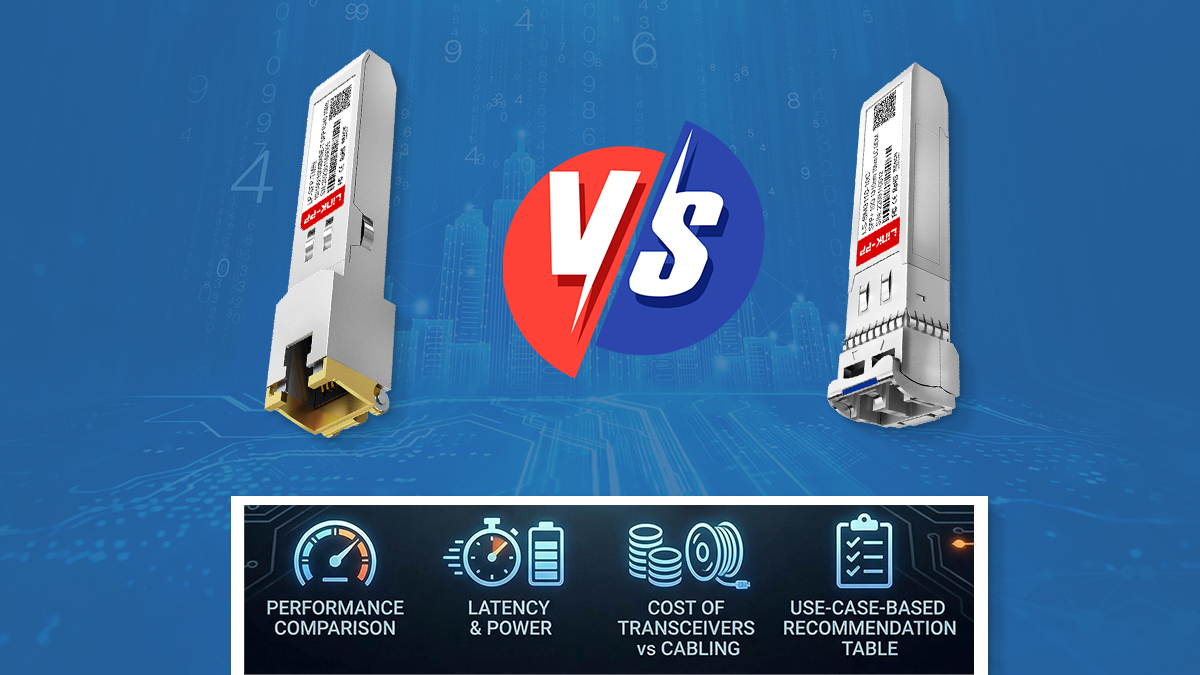

✅ 10G SFP Copper vs 10G SFP+ Fiber: Which Should You Buy?

When planning a 10-gigabit Ethernet upgrade, one of the first decisions IT buyers must make is whether to use 10G SFP copper or 10G SFP+ fiber optics. Both technologies support 10Gbps speeds and use the same SFP+ form factor, but they differ significantly in performance, power consumption, cost structure, and ideal deployment scenarios. Below is a structured comparison to help you choose the right solution for your network.

Performance Comparison

| Feature |

10G SFP Copper |

10G SFP+ Fiber |

| Maximum Practical Distance |

Up to ~100m (Cat6a/Cat7) |

Hundreds of meters to kilometers |

| Signal Medium |

Electrical over copper |

Optical over fiber |

| Transmission Interference |

Susceptible to EMI/RFI |

Immune to electromagnetic noise |

| Connector Type |

RJ45 |

LC (typical) |

10G SFP copper is optimized for short-distance links, while 10G SFP+ fiber excels in longer-distance and interference-sensitive environments.

Latency and Power Usage Differences

Latency and power consumption are important factors, especially in high-density or performance-critical networks:

-

Latency:

Fiber transceivers generally exhibit lower latency compared to copper, due to simpler signal processing.

-

Power Usage:

10G SFP copper modules typically consume more power (often in the 2.5W–3.5W range per port) as they must handle complex electrical signal equalization. In contrast, fiber SFP+ optics often draw significantly less power.

These differences can impact:

Cost of Transceivers vs Cabling

The total cost of ownership for 10GbE deployments depends on both transceiver prices and cabling infrastructure:

| Cost Component |

10G SFP Copper |

10G SFP+ Fiber |

| Transceiver Unit Price |

Moderate |

Higher |

| Cabling Cost |

Lower (Cat6a/Cat7) |

Higher (fiber + terminations) |

| Installation Complexity |

Lower |

Higher |

| Maintenance Effort |

Minimal |

Higher (fiber cleaning & testing) |

10G SFP copper tends to have lower upfront deployment costs when copper cabling is already in place, whereas fiber may incur higher cabling and maintenance expenses but offers long-term scalability.

Use-Case-Based Recommendation Table

| Scenario |

Recommended Option |

| Short-range connectivity within rack/rack row |

10G SFP Copper |

| Long-distance links (between buildings / floors) |

10G SFP+ Fiber |

| Environments with heavy EMI / electrical noise |

10G SFP+ Fiber |

| Budget-conscious upgrades with existing copper |

10G SFP Copper |

| Data center spine / core layer with future growth |

10G SFP+ Fiber |

Summary:

-

Choose 10G SFP copper when you need cost-effective, short-distance 10GbE connections using existing copper infrastructure.

-

Choose 10G SFP+ fiber for longer distances, cleaner signal integrity, and future-proof scaling.

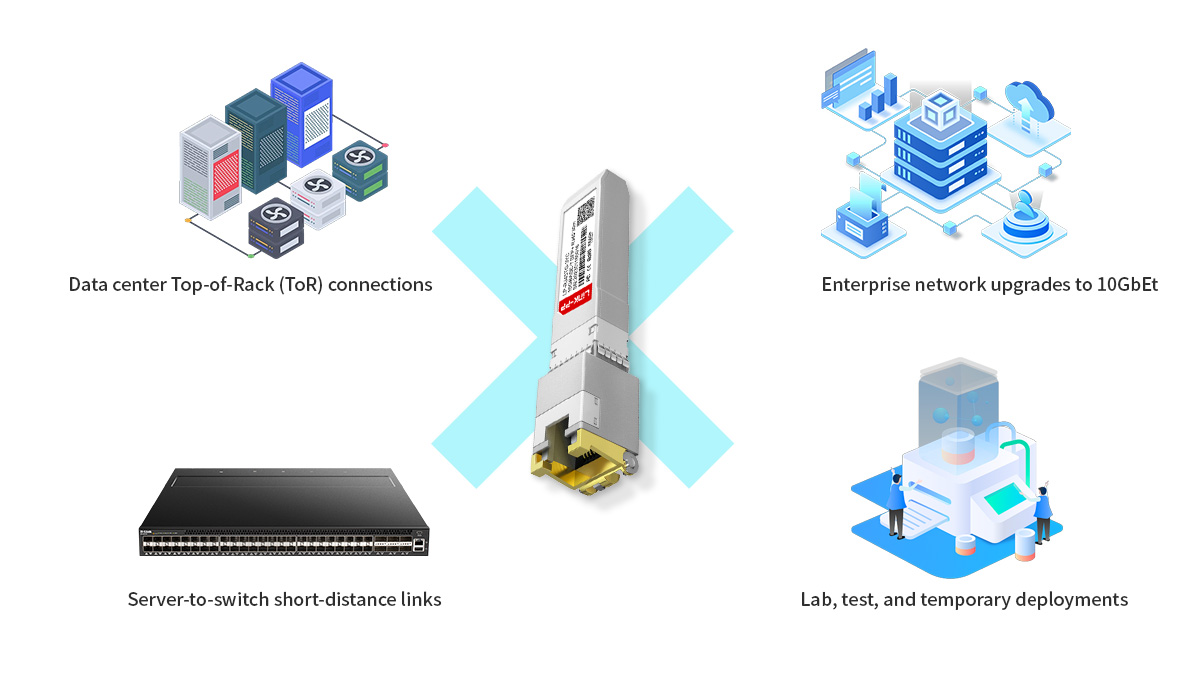

✅ Common Use Cases for 10G SFP Copper

Thanks to its flexibility and ease of deployment, 10G SFP copper is widely used in scenarios where short-distance 10GbE connectivity is required without the complexity of fiber optics. Below are the most common and practical use cases where 10G SFP copper delivers the best value.

Data Center Top-of-Rack (ToR) Connections

In data center environments, Top-of-Rack (ToR) architectures often require short, high-speed connections between servers and access switches. 10G SFP copper modules are well-suited for these deployments because:

-

Distances are typically well within the 30–100m limit

-

RJ45 cabling simplifies server additions and changes

-

Copper allows rapid provisioning without fiber management overhead

For ToR designs focused on flexibility and fast deployment rather than long reach, 10G SFP copper provides a reliable and cost-effective solution.

Enterprise Network Upgrades to 10GbE

Many enterprise networks are upgrading from 1GbE to 10GbE to support bandwidth-intensive applications such as virtualization, VoIP, and high-volume data transfers. In these cases, 10G SFP copper enables:

-

Reuse of existing Cat6a or Cat7 cabling

-

Minimal disruption during network upgrades

-

Faster migration without retraining IT staff on fiber handling

This makes 10G SFP copper particularly attractive for enterprise access and aggregation layers where link distances are limited.

Server-to-Switch Short-Distance Links

For server-to-switch connections within the same rack or adjacent racks, 10G SFP copper offers a simple and dependable option. Compared to DAC cables, copper SFP+ modules provide:

-

Greater flexibility in cable length

-

Compatibility with structured cabling systems

-

Easy replacement and reconfiguration

These advantages make them ideal for environments where cabling layouts may change frequently.

Lab, Test, and Temporary Deployments

In labs, proof-of-concept environments, and temporary network setups, ease of deployment and reuse are key priorities. 10G SFP copper modules excel in these scenarios because they:

-

Support quick setup and teardown

-

Work with standard Ethernet cabling

-

Reduce equipment investment for non-production environments

Their versatility allows teams to validate designs, test configurations, or support temporary projects without committing to permanent fiber infrastructure.

✅ How to Choose the Right 10G SFP Copper Module

Selecting the right 10G SFP copper module requires more than matching the SFP+ form factor. A structured evaluation process helps ensure compatibility, performance stability, and long-term reliability. The following step-by-step checklist is designed to guide buyers through a confident purchasing decision.

Step-by-Step Buyer Checklist

Before placing an order, review each of the following criteria to avoid common deployment issues:

Device Model Verification

Start by confirming the exact model of your switch, router, or network interface card (NIC). Even within the same vendor, different models may have varying support for 10G SFP copper modules.

Key actions:

-

Check the vendor’s official hardware compatibility list

-

Verify SFP+ port support for 10GBASE-T transceivers

-

Confirm any firmware or OS version requirements

Accurate device identification is essential for selecting a properly coded and supported module.

Distance and Cable Type

Next, evaluate your link distance and cabling infrastructure, as these directly affect achievable performance.

Considerations include:

-

Cable category in use (Cat6, Cat6a, or Cat7)

-

Total link length, including patch cords

-

Environmental factors that may introduce interference

For stable 10Gbps performance, Cat6a or higher is recommended, especially for links approaching 80–100 meters.

Power and Cooling Capacity

Because 10G SFP copper modules draw more power than fiber optics, it is important to assess your device’s power budget and thermal design.

Checklist items:

-

Maximum supported power per SFP+ port

-

Overall switch power and cooling capacity

-

Airflow direction and port density

Insufficient cooling can lead to throttling, port shutdowns, or reduced module lifespan.

Vendor Compatibility List

Finally, review the vendor compatibility list provided by the module supplier. Reputable manufacturers test their 10G SFP copper modules across a wide range of platforms to ensure stable operation.

What to look for:

-

Verified compatibility with major switch vendors

-

Clear documentation and labeling

-

Compatibility guarantees or replacement policies

Choosing a supplier with proven cross-vendor testing significantly reduces risk and simplifies deployment.

✅ Where to Buy Reliable 10G SFP Copper Modules

Selecting a dependable source for 10G SFP copper modules is critical to ensuring network stability, compatibility, and long-term performance. Beyond pricing, buyers should evaluate suppliers based on technical validation, manufacturing quality, and post-sale support. A structured approach to supplier selection can significantly reduce deployment risks.

What to Look for in a Supplier

A reliable 10G SFP copper supplier should demonstrate proven technical capability and transparent processes. The following criteria are essential when evaluating potential vendors.

Compatibility Testing

Comprehensive compatibility testing is one of the most important indicators of supplier quality. Reputable vendors test their 10G SFP copper modules across a wide range of switches, routers, and network interface cards to ensure:

-

Proper module recognition by the host device

-

Stable 10Gbps auto-negotiation and link performance

-

Consistent operation across different firmware versions

This level of testing minimizes the risk of link failures, port errors, or performance degradation after deployment.

Quality Control and Certifications

Strong quality control (QC) processes ensure consistent performance and low failure rates. Buyers should look for suppliers that implement multi-stage QC procedures, including:

-

Component-level inspection

-

Functional and thermal testing

-

Final product validation before shipment

In addition, compliance with recognized certifications such as CE, FCC, and RoHS indicates adherence to international safety and environmental standards, further reinforcing product reliability.

Warranty and Technical Support

Reliable suppliers stand behind their products with meaningful warranty coverage and technical support. Key factors to consider include:

-

Clearly defined warranty periods

-

Straightforward replacement or RMA processes

-

Access to knowledgeable technical support teams

Strong post-sale support reduces operational risk and provides confidence when deploying 10G SFP copper modules in production networks.

Why Many Buyers Choose Third-Party Manufacturers

An increasing number of enterprises and data centers choose third-party 10G SFP copper manufacturers (like LINK-PP)over OEM options. The primary reasons include:

-

Significantly lower cost compared to OEM-branded modules

-

Broad compatibility across multiple switch vendors

-

Flexible firmware coding and faster product availability

When sourced from established manufacturers with proven testing, quality control, and support practices, third-party 10G SFP copper modules can deliver reliable performance while offering substantial cost savings.

✅ FAQs About Buying 10G SFP Copper

Below are answers to the most frequently asked questions from buyers evaluating 10G SFP copper modules. These clarifications address common concerns around deployment, compatibility, and performance, helping you make a more informed purchasing decision.

Is 10G SFP Copper hot-swappable?

Yes, 10G SFP copper modules are hot-swappable in most enterprise and data center switches that support SFP+ optics. This means they can be inserted or removed without powering down the device, reducing maintenance downtime.

However, best practices include:

-

Following the switch vendor’s hot-swap guidelines

-

Avoiding frequent insertion/removal under heavy traffic

-

Allowing sufficient time for link negotiation after insertion

Can 10G SFP Copper work in any SFP+ port?

Not all SFP+ ports support 10G SFP copper modules. While the form factor is the same, successful operation depends on:

-

Power support of the SFP+ port

-

Firmware recognition of 10GBASE-T transceivers

-

Vendor-specific compatibility restrictions

Some switches limit copper module usage or require specific firmware versions. Always check the device compatibility list before purchasing.

Why does 10G SFP Copper consume more power?

10G SFP copper modules consume more power than fiber-based SFP+ optics because 10GBASE-T transmission over copper requires complex signal processing. This includes:

-

Advanced modulation and equalization

-

Error correction mechanisms

-

Auto-negotiation at multiple speeds

As a result, typical power consumption ranges from 2.5W to 3.5W, which can impact switch cooling and port density in high-density deployments.

What cable is required for stable 10G speeds?

For reliable 10Gbps performance, the recommended cable types are:

Standard Cat6 may support shorter distances (up to ~30 meters), but for consistent and future-proof operation, Cat6a or higher is strongly recommended.

✅ Summary: Is 10G SFP Copper the Right Choice for You?

10G SFP copper is a practical and cost-effective solution for delivering 10GbE performance over short distances, especially in environments where copper cabling is already in place. When used in the right scenarios, it offers a strong balance of speed, flexibility, and deployment simplicity.

Key Advantages Recap

The primary benefits of choosing 10G SFP copper include:

-

Lower deployment costs by reusing existing Cat6a or Cat7 cabling

-

Simple, plug-and-play installation with standard RJ45 connections

-

Flexible short-range connectivity for server, rack, and enterprise networks

-

Broad compatibility when using MSA-compliant, well-tested modules

These advantages make 10G SFP copper particularly attractive for budget-conscious upgrades and rapid deployments.

When 10G SFP Copper Is the Best Option

10G SFP copper is the right choice when:

-

Link distances are within 30–100 meters

-

Copper infrastructure is already installed

-

Fast deployment and easy maintenance are priorities

-

High-density fiber management is unnecessary

It performs especially well in Top-of-Rack, server-to-switch, and enterprise access-layer applications.

When to Consider Fiber Alternatives

Fiber-based SFP+ modules may be a better fit when:

-

Longer transmission distances are required

-

Lower latency and power consumption are critical

-

The environment has high electromagnetic interference

-

Future scalability beyond short-range links is planned

In these cases, multimode or single-mode fiber provides better long-term flexibility.

Final Recommendation

If your network requires reliable short-range 10GbE connectivity with minimal complexity and cost, 10G SFP copper is a smart and proven choice. For buyers seeking high-quality, fully compatible modules backed by rigorous testing and support, buy high-quality, compatible 10G SFP Copper from the LINK-PP Official Store to ensure stable performance and long-term reliability.