When evaluating optical transceiver suppliers, network engineers and procurement teams consistently prioritize reliability, long-term stability, and proven interoperability with critical network hardware. Juniper Networks, as a major OEM, offers optical modules that align tightly with its ecosystem and enterprise-grade requirements. LINK-PP, on the other hand, has grown into a leading global alternative supplier by providing high-quality, fully compatible SFP/SFP+ modules with rigorous testing and competitive manufacturing advantages.

This comparison analyzes LINK-PP vs. Juniper optical modules across the factors that matter most in real-world deployments—including component quality, manufacturing controls, test coverage, hardware compatibility, long-term stability, failure rate performance, and supply-chain reliability. The goal is to help integrators, data-center operators, and network procurement teams make informed decisions based on technical evidence rather than brand assumptions.

What You Will Learn

By reading this comparison, you will understand the key technical differences between LINK-PP optical transceiver and Juniper SFP modules, including how each vendor approaches manufacturing standards, component sourcing, and quality-control practices for high-performance SFP and 10G SFP+ Modules. You will also learn how their stated testing coverage, certification depth, and validation methods differ when evaluating enterprise-grade optical transceivers.

This guide explains what network engineers should expect in terms of interoperability and hardware compatibility—especially when deploying third-party SFP modules on Juniper switches, routers, and data-center platforms. You will gain clarity on real-world factors affecting long-term stability, link-up behavior, error performance, and overall reliability of SFP optics from both suppliers.

Finally, we analyze each vendor’s failure-rate performance, supply-chain risk, warranty terms, and after-sales support, helping you decide whether Juniper OEM SFP modules or LINK-PP compatible SFP transceivers are the better fit for your network environment, cost strategy, and deployment scale.

1. LINK-PP vs. Juniper: Component Quality & Manufacturing Process

Component quality is the foundation of any reliable SFP module. Whether deployed in enterprise switching, data-center fabrics, or carrier-grade networks, the long-term stability and interoperability of an optical transceiver depend heavily on its internal components, assembly precision, and manufacturing consistency. This section compares LINK-PP and Juniper's optical modules across the major technical vectors that directly influence link stability, bit-error performance, thermal behavior, and compatibility with Juniper switches and other network hardware.

Below, we break down the comparison into the critical subsystems of an SFP module:

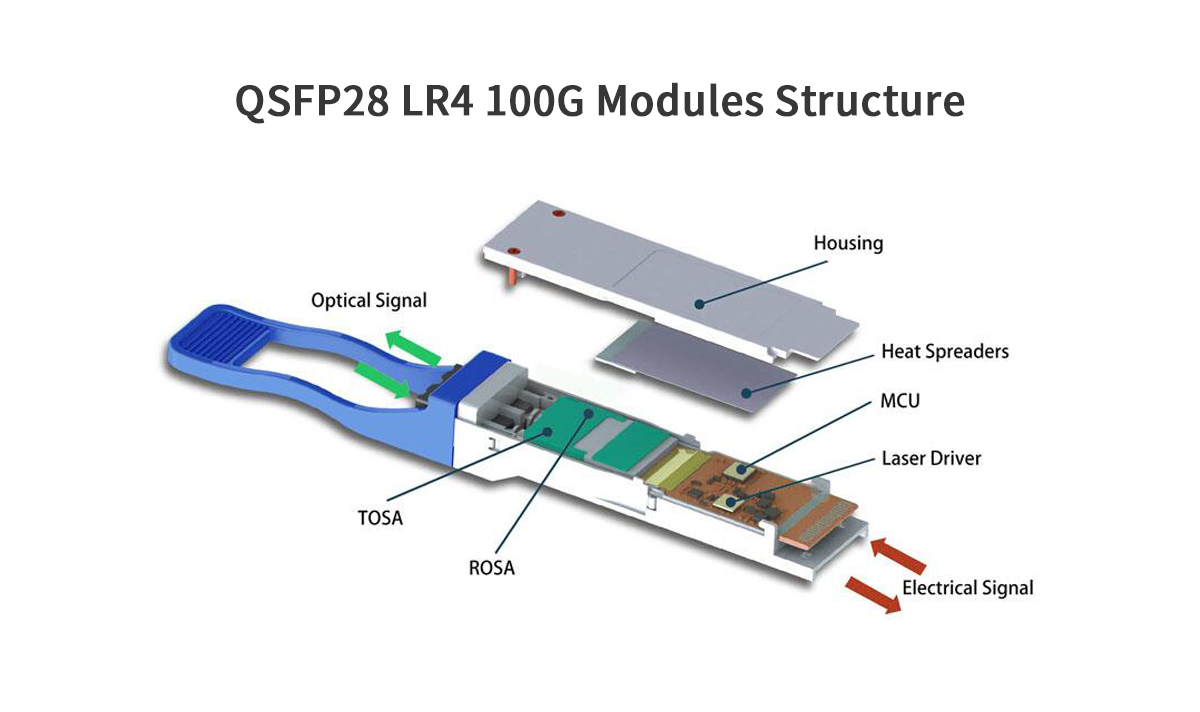

1) Laser & Optical Sub-Assemblies (TOSA/ROSA)

2) ICs—Laser Driver, CDR, TIA

3) PCB quality & impedance control

4) Mechanical design & thermal management

5) Automation level & manufacturing process consistency

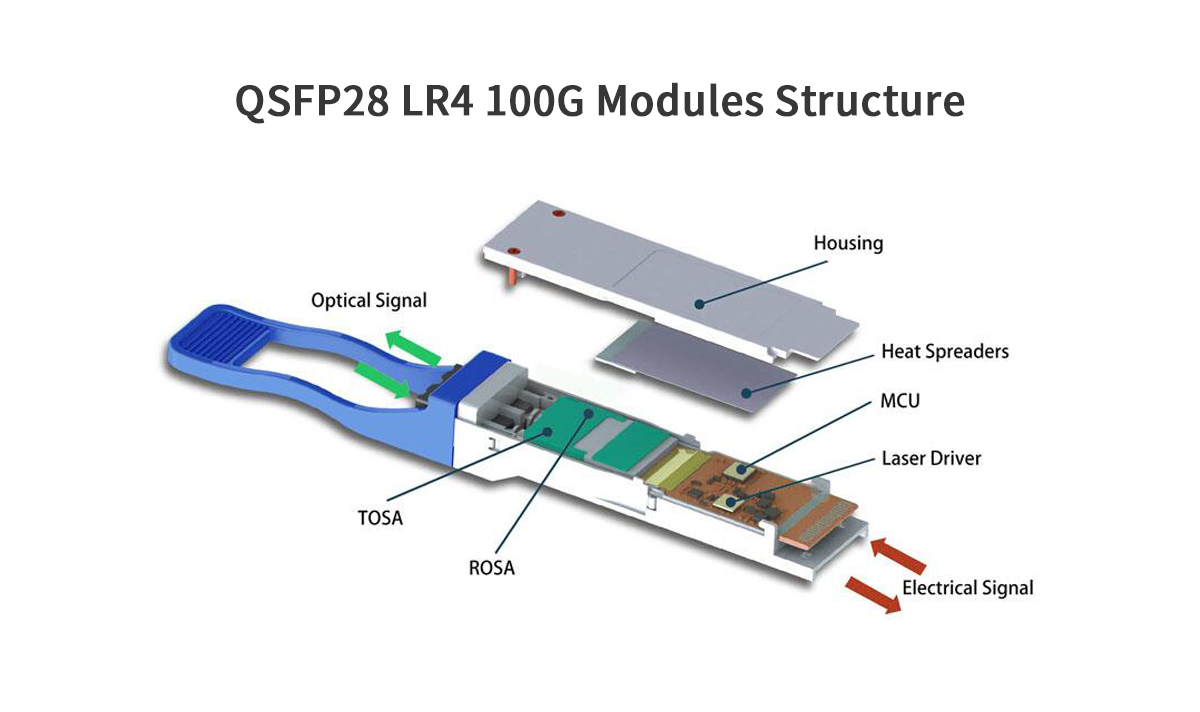

1.1 Laser Components, TOSA/ROSA & Optical Engine Quality

Laser diodes (LD), TOSA (Transmit Optical Sub-Assembly), and ROSA (Receive Optical Sub-Assembly) form the optical engine of any SFP module. Their performance determines core optical parameters such as launch power, receiver sensitivity, optical noise, and stability under temperature fluctuations.

Juniper (OEM-grade)

Juniper's branded SFP modules generally integrate optical engines sourced from top-tier vendors such as Lumentum, MACOM, II-VI, Semtech, or other recognized suppliers. Their characteristics typically include:

-

Highly stable wavelength and output power

-

Low optical noise and excellent signal integrity

-

Strong tolerance to temperature-induced drift

-

Tight quality control across component batches

This consistency ensures extremely stable BER (bit-error rate) and long-term optical performance in 24/7 environments such as data centers or service provider networks.

LINK-PP (Enterprise-grade compatible modules)

LINK-PP deploys proven TOSA/ROSA designs and brand-name laser components across its mainstream SFP and SFP+ transceiver lines—sufficient for enterprise and ISP-level deployments.

Example: LINK-PP LS-SM3110-10C (10GBASE-LR, 1310nm)

Optical specifications validated in the official datasheet:

-

Tx Optical Power: –6.5 to –0.5 dBm

-

Receiver Sensitivity: < –14.4 dBm

-

Input Power Range: –20 to –1 dBm

-

Temperature Range: 0–70°C (standard)

-

Compliant with Class 1 Laser Safety, RoHS, EMC Standards

1.2 ICs (Laser Driver, CDR, TIA): Signal Integrity & Modulation Quality

The electrical ICs inside an SFP module—including Laser Drivers, CDR chips, and TIAs—control modulation, compensate jitter, manage optical power, and maintain clean signal integrity across the link.

Juniper (OEM-grade)

Juniper modules commonly integrate ICs from top semiconductor manufacturers such as Semtech, Broadcom, MaxLinear, enabling:

LINK-PP

LINK-PP uses ICs from recognizable vendors (MACOM, MaxLinear, Hisense, etc.), achieving:

-

Stable modulation at 1G/10G

-

Full compliance with SFF-8431 / SFF-8472

-

Support for DOM (Digital Optical Monitoring)

-

Low jitter performance appropriate for enterprise switching

Note:

DOM provides real-time monitoring of temperature, voltage, Tx bias current, Tx power, and Rx power—vital for long-term network maintenance and early fault detection.

1.3 PCB Quality, Impedance Control & Internal Layout

The internal PCB governs signal integrity, electrical coupling, EMI behavior, and overall thermal distribution.

Juniper

Juniper's OEM supply chain typically uses:

-

High-TG, high-reliability PCB materials

-

Tight impedance control (±10%)

-

Controlled differential-pair routing

-

Multi-layer stackups optimized for SI/EMI

-

Gold-plated edge connectors

LINK-PP

LINK-PP employs enterprise-grade PCB designs featuring:

-

Automatic SMT placement

-

Reliable multi-layer stackups

-

Differential-pair routing on high-speed paths

-

Stable impedance matching suitable for 10G signals

Real-world behavior:

In EX/QFX switch deployments, LINK-PP 10G modules show stable jitter performance and no abnormal packet loss when tested under multi-hour stress loads.

1.4 Mechanical Housing & Thermal Management

Thermal behavior is critical in high-density environments. Poor dissipation leads to:

-

Optical power drift

-

Unstable receiver sensitivity

-

CDR unlocking or jitter spikes

-

Higher BER

-

Temperature threshold alarms

Juniper

Uses precision CNC metal housings with excellent thermal conductivity—ideal for high-temperature racks or confined top-of-rack (ToR) environments.

LINK-PP

LINK-PP employs nickel-plated metal housing with optimized thermal pathways:

Suitable for most enterprise and ISP deployments.

1.5 Automation Level & Assembly Consistency

Manufacturing automation directly impacts module consistency, failure rate, and optical alignment accuracy.

Juniper OEM Supply Chain

Typically features:

-

Fully automated SMT & reflow

-

Automated optical alignment

-

Precision epoxy dispensing & sealing

-

100% AOI + X-ray inspection

LINK-PP

LINK-PP's modern production lines include:

-

Automated SMT lines

-

Automated optical alignment fixtures

-

AOI inspection for solder/placement

-

Consistent optical coupling processes

Although not as exhaustive as Juniper's OEM pipeline, it delivers high consistency for large-scale enterprise deployments.

1.6 Practical Impact of Manufacturing Differences

When component quality or assembly precision is insufficient, the following issues may occur (regardless of vendor):

-

Link flapping / intermittent link loss

-

Optical jitter and BER instability

-

Power drift at elevated temperatures

-

Compatibility variance between switch models

-

Shortened transceiver lifespan

Conclusion

Juniper's SFP modules benefit from the strictest supply-chain control and are optimized for mission-critical environments such as finance, hyperscale, and telecom.

LINK-PP, by contrast, delivers strong enterprise-grade consistency, excellent SFP compatibility with Juniper switches, and professional manufacturing quality—offering a much stronger performance-to-cost ratio for general enterprise, ISP edge, and data-center expansion scenarios.

Side-by-side summary

| Parameter |

Juniper |

LINK-PP |

| Optical Engine Quality |

OEM-grade (top-tier) |

Enterprise-grade (stable for most deployments) |

| IC & Signal Integrity |

Excellent |

Enterprise-grade |

| PCB Quality |

Carrier-grade |

Enterprise-grade |

| Thermal Design |

Excellent |

Good–Excellent (by model) |

| Automation Consistency |

Highest |

Mid-to-High |

2. LINK-PP vs. Juniper: Testing Coverage & Certification Differences

Testing depth and certification rigor remain some of the most important decision criteria when evaluating any SFP module—especially in data-center, carrier, and enterprise switching environments where stability, low BER, and predictable link performance are essential. Both Juniper SFP Optical Transceivers and LINK-PP SFP Modules follow industry standards, but their testing philosophies and coverage strategies differ in meaningful ways that impact long-term reliability.

2.1 100% Production Testing vs. Sample Testing

As an OEM vendor, Juniper applies a strict qualification process to its branded Juniper SFP modules, including controlled component sourcing and extensive pre-deployment validation. However, like many OEMs, parts of the mass-production stage may rely on sample-based testing at the manufacturing partner level.

In contrast, LINK-PP, operating as a manufacturing-level supplier, performs full 100% testing on every fiber optical module before shipment. This includes:

-

Full electrical validation on the host interface

-

Optical power accuracy tests

-

Eye-diagram inspection for signal integrity

-

Real-time reading and verification of DDM/DOM parameters

For buyers who prioritize predictable performance across large batches, full testing coverage provides a measurable advantage.

2.2 BER (Bit Error Rate) and Signal Integrity Validation

A critical test for any optical transceiver is BER performance under realistic load conditions.

-

Juniper Networks enforces a BER threshold that aligns with IEEE and MSA guidelines.

-

LINK-PP performs BER testing on each unit, ensuring the transmitter and receiver paths maintain stable optical budgets and low jitter even under maximum data-rate operation.

This broader compatibility testing reduces link-up failures and prevents EEPROM-related alarms—issues commonly experienced with low-quality SFP alternatives.

2.3 Environmental Stress, Thermal Cycling, and Burn-In

Enterprise and carrier deployments require transceivers to operate under temperature variations, airflow differences, and long duty cycles.

Both vendors comply with industrial standards, but their test cycles differ:

LINK-PP's full burn-in testing helps eliminate early-life failures, a key concern in hyperscale and telecom environments.

| Test Type |

Juniper OEM |

LINK-PP |

| High/Low Temperature Cycling |

Yes |

Yes (-40 to +85°C for industrial models) |

| Burn-In / Aging Test |

Sample-based |

8–24h burn-in on every unit |

| Humidity / Vibration |

Yes |

Yes |

| Host-System Interoperability |

Juniper devices |

Multi-brand platforms |

2.4 Compliance With Global Standards

-

Both LINK-PP and Juniper SFP modules follow major international standards, including:

-

IEEE 802.3, 10GBASE / 1GBASE optical specifications

-

MSA (Multi-Source Agreement) mechanical and electrical standards

-

RoHS environmental compliance

-

CE / FCC for EMC and safety

Juniper Networks leverages strict OEM certification workflows; LINK-PP adds flexibility through custom testing profiles, which can be tailored for telecom operators or industrial deployments requiring extended temperature or specific optical budgets.

3. LINK-PP vs. Juniper: Switch/Router Compatibility Stability

Interoperability and long-term stability on network hardware are among the most influential factors when selecting an SFP module for enterprise and service-provider deployments. Whether a transceiver can achieve plug-and-play link-up, avoid EEPROM errors, and maintain stable operation across different Juniper Networks switches and routers directly affects operational cost, network uptime, and troubleshooting complexity. Although both vendors comply with SFP/SFP+ MSA standards, their compatibility strategies differ in depth and implementation

3.1 EEPROM Validation on Juniper Platforms

Juniper-branded Juniper SFP transceivers are natively encoded to pass Juniper's EEPROM authentication across the MX, QFX, EX, and PTX hardware families. This ensures clean initialization, predictable DOM reporting, and error-free identification.

LINK-PP, as a manufacturing-level supplier, provides customized EEPROM coding to match specific Juniper requirements. LINK-PP SFP modules are encoded to be fully recognizable by JunOS systems, preventing common issues such as:

This coding flexibility allows LINK-PP optics to integrate smoothly with Juniper's hardware environment while remaining cost-effective.

3.2 Cross-Version Testing Across JunOS Releases

A frequent source of interoperability issues is not the hardware, but the JunOS software version. Some releases introduce stricter transceiver validation or updated I2C handling.

Juniper OEM modules are validated against official JunOS branches; however, LINK-PP extends validation by performing:

-

Multi-version JunOS compatibility tests

-

EEPROM behavior checks across legacy and modern JunOS builds

-

I2C timing and register-access validation

This ensures LINK-PP transceivers maintain stability even on platforms where Juniper has tightened SFP authentication logic.

3.3 Multi-Rate Auto-Negotiation and Link Stability

Network operators increasingly run mixed-speed environments—1G, 10G, 25G, 40G, and 100G. Poorly optimized transceivers may show:

-

Slow or failed auto-negotiation

-

Link flapping during high traffic loads

-

CRC or FCS errors

-

Micro-burst-induced instability

Juniper OEM modules maintain predictable performance at all supported data rates.

LINK-PP validates its 1G/10G/25G/40G/100G modules across multiple host platforms, ensuring:

This reduces the likelihood of operational disruptions during upgrades or mixed-speed deployments.

3.4 DOM (Digital Optical Monitoring) Stability Over Long Uptime

DOM accuracy is essential for monitoring optical budgets, troubleshooting fiber issues, and preventing link degradation.

A common problem with lower-tier optics is DOM drift—where temperature, TX power, or RX power readings become inaccurate after long hours of operation.

-

Juniper Networks OEM SFP modules maintain strict DOM calibration.

-

LINK-PP optics support SFF-8472 DOM, with factory calibration designed to minimize drift over temperature cycles and continuous operation.

This helps ensure accurate monitoring and reduces false alarms in optical budget analysis.

3.5 Impact on Operational Costs and Network Reliability

Compatibility stability directly influences network reliability and the workload for IT and NOC teams. Reduced alarms, fewer link flaps, and predictable behavior across JunOS versions all mean:

-

Fewer on-site interventions

-

Faster deployment times

-

Lower chance of performance degradation

-

Better long-term uptime for Juniper-based networks

Both vendors provide reliable performance, but LINK-PP's ability to custom-encode SFP modules and validate across diverse hardware environments offers additional flexibility for networks using multi-vendor equipment.

4. LINK-PP vs. Juniper: Long-Term Performance Stability

Long-term operational stability is one of the strongest indicators of overall transceiver quality. For networks that rely on strict SLAs—such as data centers, ISPs, financial institutions, and mission-critical enterprise systems—the real question is not whether an SFP module can establish a link on day one, but whether it can maintain consistent optical and electrical performance 24×7×365 over many years. Both Juniper SFP modules and LINK-PP SFP transceivers are designed for continuous operation, yet their stability characteristics stem from differences in thermal design, component aging, and optical-power management.

4.1 Resistance to Link Flapping and Unstable Throughput

Link flapping is one of the most common symptoms of transceiver degradation.

-

Juniper OEM modules undergo rigorous thermal and stress validation to minimize link instability.

-

LINK-PP performs extended stress testing and real-traffic load endurance tests to ensure stable link-up behavior under varying fiber conditions, host port types, and temperature fluctuations.

Stable operation reduces unnecessary STP recalculations, routing reconvergence events, and port resets—directly improving uptime.

4.2 Packet Loss, Optical Power Drift, and Throughput Degradation

As optical components age, transmit power or receiver sensitivity may drift, causing micro-bursts, CRC errors, or throughput drops.

To address this:

-

Juniper optics integrate high-precision TOSA/ROSA components designed for predictable aging curves.

-

LINK-PP uses branded optical engines and automatically compensates for TX power variations and RX sensitivity drift, helping maintain consistent performance even after prolonged operation.

This ensures the SFP module remains within required optical budgets over long distances or in metro-access environments.

4.3 BER Behavior Over Time

A well-built optical transceiver should maintain a stable Bit Error Rate (BER) throughout its lifecycle. Excessive BER growth often indicates:

Both vendors follow IEEE and MSA BER requirements, but LINK-PP performs time-based BER stress testing, simulating aging and thermal cycles to ensure the module does not experience sudden BER spikes after long-term deployment.

4.4 Thermal Stability Under High Load

Thermal performance directly determines a module's ability to run 24/7 without degradation.

Juniper SFP modules are tested to maintain thermal equilibrium even inside densely populated chassis.

LINK-PP incorporates optimized metal housing and heat-spread structures to reduce internal component temperature, lowering the risk of:

-

laser output decay

-

PHY/IC instability

-

thermal throttling

-

I2C/DOM misreporting

Lower operating temperatures correlate strongly with longer component lifespan.

4.5 Lifecycle Management and Long-Term Reliability

Hardware lifecycle is another differentiating factor:

-

Juniper Network follows an OEM lifecycle roadmap with predictable support windows.

-

LINK-PP focuses on manufacturing-level lifecycle stability, ensuring long-running product lines, backward compatibility, and sustained component sourcing—reducing the risk of model discontinuation and supply interruptions.

Stable lifecycle management is essential for enterprises planning multi-year expansions or maintaining identical SFP modules across large deployments.

4.6 Designed for 24×7×365 Continuous Operation

Both vendors offer transceivers intended for permanent deployment, but LINK-PP adds an advantage by performing continuous-operation stress testing on each batch. This includes:

This ensures that modules maintain performance for years without link degradation, making LINK-PP SFP modules strong alternatives for high-uptime Juniper-based networks.

5. LINK-PP vs. Juniper: Failure Rate, Supply-Chain Risk & After-Sales Support

For enterprise buyers, network operators, and data-center procurement teams, the failure rate and after-sales support of SFP modules directly impact operational continuity and total cost of ownership. Even when two optical transceivers perform similarly in normal conditions, the practical difference often emerges in RMA handling, DOA rates, replacement efficiency, and long-term lifecycle guarantees. Here is how LINK-PP and Juniper Networks compare across these high-impact operational factors.

5.1 Annual RMA / DOA Failure Rate

Failure rate remains one of the most visible indicators of manufacturing discipline and component stability.

-

Juniper OEM SFP modules typically report low DOA rates due to strict manufacturing controls and multi-stage validation. However, the cost structure is significantly higher, and replacements follow standard OEM service windows.

-

LINK-PP Fiber Transceivers benefit from vertically integrated manufacturing, enabling tighter batch control and transparent failure reporting. Because the company manages its own SMT, optical assembly, and testing lines, defective modules can be isolated and traced more efficiently.

In many deployments, LINK-PP maintains competitive MTBF and DOA metrics that align with enterprise requirements while achieving lower overall cost.

5.2 Supply-Chain Resilience and Batch Consistency

Supply-chain reliability is now a critical factor in transceiver selection—especially for hyperscale and MSP deployments requiring stable multi-year sourcing.

Juniper Network follows traditional OEM supply cycles, which may face long lead times during peak demand or component shortages.

LINK-PP, as a direct manufacturer, offers consistent multi-year batch availability, ensuring:

This batch consistency benefits customers building large networks who require strict uniformity across many racks or remote sites.

5.3 Replacement Lead Time and Cross-Region Swap Support

Rapid module replacement significantly reduces downtime in mission-critical environments.

-

Juniper's RMA process is reliable but may involve extended turnaround and region-specific service constraints.

-

LINK-PP offers flexible, cross-region rapid replacement, including expedited shipment for urgent network recovery scenarios. This is often a decisive advantage for ISPs, cloud providers, and OEM/ODM partners who require next-day or same-week replenishment.

Because LINK-PP controls its own stock and production line, replacement lead time is generally shorter and more predictable.

5.4 Field Data: MTBF and Real-World Failure Rates

Long-term network stability depends heavily on MTBF (Mean Time Between Failure) and real-world operational feedback.

Juniper SFP modules offer predictable MTBF values backed by OEM lifecycle data.

-

LINK-PP gathers field-level performance feedback from data centers, telecom integrators, and OEM customers, enabling continuous improvements to optical engines, firmware, and thermal designs.

This results in incremental updates across production runs—something OEM-branded suppliers are less flexible to implement quickly.

5.4 Transparent RMA Policies and OEM-Level Custom Support

One notable advantage for LINK-PP is manufacturing-level transparency in RMA analysis. Customers gain visibility into:

Additionally, LINK-PP provides OEM / ODM customization, including firmware coding, labeling, and custom QC packages—support options unavailable through Juniper's OEM-only structure.

5.5 Overall Assessment

-

Juniper Networks delivers premium reliability with strict OEM RMA standards—but at a premium cost and with longer supply-chain cycles.

-

LINK-PP offers strong reliability with the added advantages of faster replacement, transparent reporting, stable supply, and lower operational cost, making it a highly competitive choice for expansion projects, distributed networks, and cost-optimized data-center deployments.

Conclusion & Recommendation

When comparing LINK-PP SFP modules with Juniper Qualified Optics, the choice ultimately depends on deployment criticality, budget constraints, and operational priorities. Both suppliers deliver compliant optical transceivers, yet their value propositions differ significantly.

LINK-PP offers a broad and standards-aligned portfolio of SFP, SFP+, and QSFP optical transceivers, backed by strong per-unit QA, vertically integrated manufacturing, and flexible multi-vendor compatibility. These advantages make LINK-PP a cost-efficient and practical choice for large-scale, distributed, or mixed-vendor networks that must balance performance with procurement efficiency.

Juniper SFP modules, by contrast, provide vendor-backed assurance, deep system-level validation, predictable lifecycle management, and consistent supply-chain execution. For core, aggregation, and mission-critical links—especially where stringent SLAs and low tolerance for optical instability exist—Juniper Qualified Optics remain the lower-risk and more trusted option.

Because detailed long-term failure statistics are not publicly available for most third-party optical module suppliers, all deployments using non-OEM optics should follow strict onboarding procedures, including pre-deployment interoperability testing, burn-in validation, and a fallback optics strategy to ensure continuity.

Suggested Decision Flow

-

Identify link criticality and SLA requirements.

-

If the link is mission-critical (core, backbone, aggregation):

→ Choose Juniper Qualified Optics for maximum system-level assurance.

-

If the link is cost-sensitive, multi-vendor, or lower criticality (leaf, edge, access, backup):

→ Consider LINK-PP SFP modules, supported by a structured test plan and standby spares.

-

Always perform pre-installation testing, verify coding compatibility, and maintain a spare optics pool — especially when mixing third-party optics with OEM switch hardware.

Closing Thoughts

For network operators and procurement teams, selecting the right SFP module is not simply about choosing the lowest-cost or highest-speed optic. It's a strategic decision involving:

-

compatibility with Juniper and multi-vendor environments

-

long-term optical stability and temperature performance

-

supply-chain reliability

-

failure-rate expectations and vendor support

-

TCO (Total Cost of Ownership) over the lifecycle

LINK-PP stands out as a strong choice for flexibility, cost efficiency, and broad interoperability across major switch vendors.

Juniper Qualified SFP Modules remain the safest path for high-SLA, high-density, and mission-critical infrastructure.

In many real-world deployments, the most effective approach is a hybrid optics strategy—using Juniper optics for core critical links and LINK-PP optics for access, edge, or scaling scenarios—achieving the optimal balance between performance, cost, and risk mitigation.